Blog

What is Wire Cutting and How Does it Work for Electronics and DIY Projects

Wire cutting is a fundamental technique used in various electronics and DIY projects, transforming the way we approach wiring and connectivity. According to industry expert John Smith, a leading authority on electrical engineering, "Effective wire cutting not only streamlines the assembly process but also ensures optimal performance of electronic devices." This quote encapsulates the essence of wire cutting's significance in modern technology and crafts.

In a world where precision and efficiency are paramount, understanding the principles of wire cutting is essential for both professionals and hobbyists alike. Whether you are assembling a custom circuit board or repairing household appliances, mastering wire cutting techniques can greatly enhance your project outcomes. From selecting the right cutting tools to understanding wire types and gauge, a comprehensive grasp of wire cutting facilitates safer and more reliable electronic solutions.

As the demand for customized and efficient electronic setups continues to rise, the art of wire cutting stands at the forefront. This introduction serves as a gateway to explore the various aspects of wire cutting, its applications, and best practices, ultimately empowering readers to harness this indispensable skill in their projects.

Understanding Wire Cutting in Electronics and DIY Projects

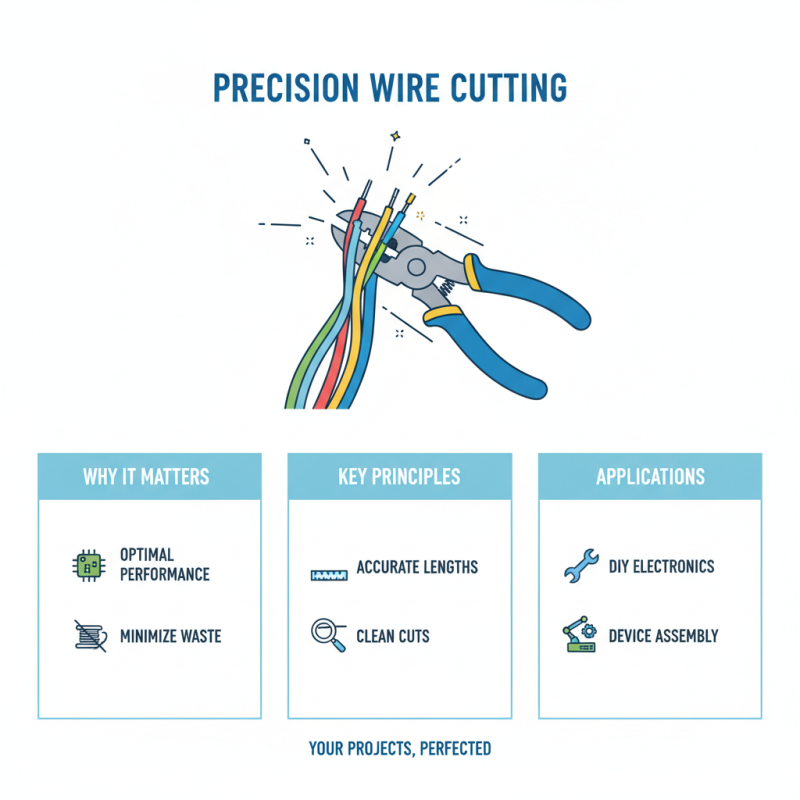

Wire cutting is a crucial process in the realm of electronics and DIY projects, providing the means to create custom lengths of wire for various applications. Understanding the principles behind wire cutting can significantly enhance the effectiveness and precision of electronic assembly. When engaging in a project, whether it’s building a new device or repairing an existing one, having the correct wire length ensures optimal performance and minimizes wasted materials.

In DIY projects, wire cutting simplifies organizational aspects and improves workflow efficiency. It allows hobbyists and professionals alike to tailor their wire installations according to specific requirements, such as circuit layouts or connection points. Through proper wire cutting, individuals can prevent tangling, reduce clutter, and enhance the overall aesthetic of their projects. Furthermore, mastering the technique of wire cutting, including measurement and tools necessary for clean cuts, enables project creators to gain a deeper understanding of the materials they work with, fostering greater innovation and creativity in their designs.

Essential Tools and Materials for Wire Cutting Tasks

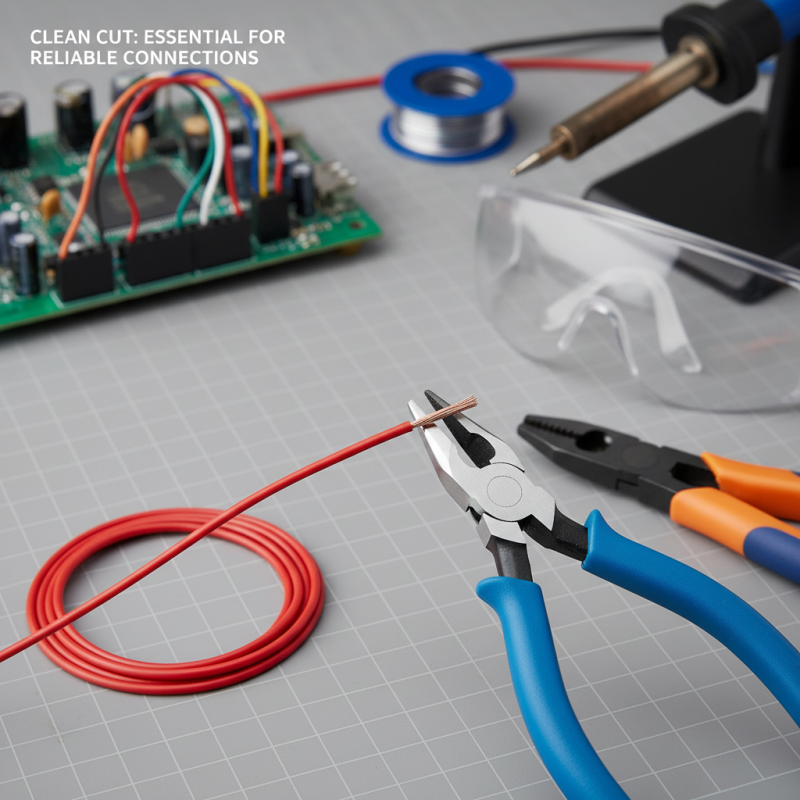

When it comes to wire cutting for electronics and DIY projects, having the right tools and materials is essential for achieving precise and efficient results. One of the fundamental tools required is a quality wire cutter, which allows for clean and accurate cuts without fraying the wire. Different types of wire cutters are available, such as flush cutters for clean edges and diagonal cutters for more challenging jobs. Having a versatile pair of wire strippers is also crucial, as they help remove insulation from the wire without damaging the conductor underneath.

In addition to tools, various materials are important for successful wire cutting tasks. Insulated wires in different gauges are commonly used, so it’s helpful to have a selection that matches the specifications of your project. Heat-shrink tubing is another critical material, as it provides insulation and protection for exposed wire sections. Electrical tape can also be used to secure connections and prevent short circuits. Keeping these essential tools and materials on hand will ensure that your wire cutting tasks are executed smoothly and effectively, enhancing the overall quality of your projects.

Step-by-Step Guide to Wire Cutting Techniques

Wire cutting is an essential skill in electronics and DIY projects, allowing for the precise manipulation of wires to suit various applications. To begin, gather the necessary tools: wire cutters, strippers, and safety gear like goggles. Start by measuring the length of wire needed for your project, ensuring to leave a little extra for errors. Use the wire cutters to achieve a clean cut; this is important to avoid frayed edges that can complicate connections later.

Once the wire is cut, stripping the insulation is the next crucial step. Select a suitable wire stripper and adjust it according to the wire gauge you are using. Position the wire in the stripper's jaws and squeeze gently to remove a small section of insulation from the end, exposing the metal conductor. Be careful not to nick the wire itself, as this can weaken it. After stripping, the wire is ready to be connected to components such as terminals, twinned wires, or soldered connections, making your DIY project come to life.

Common Applications of Wire Cutting in Electronics

Wire cutting is a fundamental process in electronics and DIY projects, playing a critical role in various applications. In the realm of electronics, wire cutting is essential for creating precise connections in circuits. According to industry reports, the demand for wire cutting services in electronics manufacturing has witnessed a steady growth of about 5% annually over the past few years. This trend is largely driven by the increasing complexity of electronic devices, such as smartphones and laptops, which require intricate wiring solutions to ensure functionality.

In DIY projects, effective wire cutting techniques allow hobbyists and professionals alike to customize electronics to suit specific needs. Common applications include crafting personalized lighting solutions, building audio equipment, and creating custom circuit boards. With the rise of the maker movement, a significant 30% of adults in the U.S. have engaged in DIY electronics, showcasing the popularity and necessity of wire cutting skills in everyday projects.

Tips: Always use high-quality wire cutters to ensure clean cuts, as frayed wires can lead to poor connectivity and potential failures in your electronic projects. Additionally, measure twice before cutting to prevent any waste of materials and ensure that all components fit perfectly within your design. Lastly, familiarizing yourself with the different types of wires and their specific cutting requirements will enhance the efficiency and safety of your work.

Safety Tips and Best Practices for Wire Cutting

When engaging in wire cutting for electronics or DIY projects, prioritizing safety is paramount. Always ensure you are wearing appropriate personal protective equipment (PPE) such as safety goggles to shield your eyes from flying wire fragments. Additionally, use gloves to protect your hands from sharp edges and to maintain a firm grip on tools. It's also wise to work in a well-lit area to minimize the risk of accidents.

Tips: Before cutting any wire, double-check that the power source is turned off. This not only prevents electrical shock but also provides clarity on what you're handling. Use the right type of wire cutter for the job; whether it’s a pair of diagonal cutters or wire strippers, having the correct tool makes the process safer and more efficient. Always cut away from yourself and others to avoid injury.

Moreover, keeping your workspace organized can significantly reduce hazards. Clear any clutter, and ensure that tools are within easy reach but stored safely when not in use. After completing your project, dispose of any wire scraps responsibly to avoid tripping hazards in your workspace. By following these best practices, you can enjoy a safer and more productive wire cutting experience.

Wire Cutting Tools and Their Uses

Related Posts

-

Ultimate Guide to Mastering Wire Cutting Techniques for Precision Engineering

-

201 Digital Tips for Mastering Wire Cutting Techniques

-

Unveiling Wire Cutting Techniques: A Comprehensive Study on Precision and Innovation in Manufacturing

-

Innovative Examples of Best Wire Harness Manufacturing Practices in 2023

-

Innovative Harness Assembly Solutions for Enhanced Efficiency and Performance

-

Exploring Innovative Harness Wire Alternatives for Enhanced Connectivity Solutions

Toll Free: (888) 802-2505

Phone: (256) 845-1255 or (256) 845-4493

Fax: (256) 845-1321 or (256) 845-4468

© 2025 Heritage Wire Harness, LLC