Blog

How to Choose the Right Wire Harness Manufacturing Service for Your Project

In today's rapidly evolving technological landscape, selecting an appropriate wire harness manufacturing service is crucial for the success of your project. According to a recent industry report by MarketsandMarkets, the global wire harness market is projected to reach USD 54.2 billion by 2025, driven by demand in automotive, aerospace, and telecommunications sectors. This growth underscores the importance of understanding the complexities of wire harness manufacturing, including design specifications, material sourcing, and compliance with safety standards.

With a multitude of manufacturers available, it is essential to evaluate each service provider's capabilities, including their expertise in custom solutions and quality assurance practices. Making informed decisions in this area can significantly impact not only production timelines but also the reliability and performance of the final product, making it imperative for project managers to prioritize thorough research in their selection process.

Factors to Consider When Evaluating Wire Harness Manufacturing Services

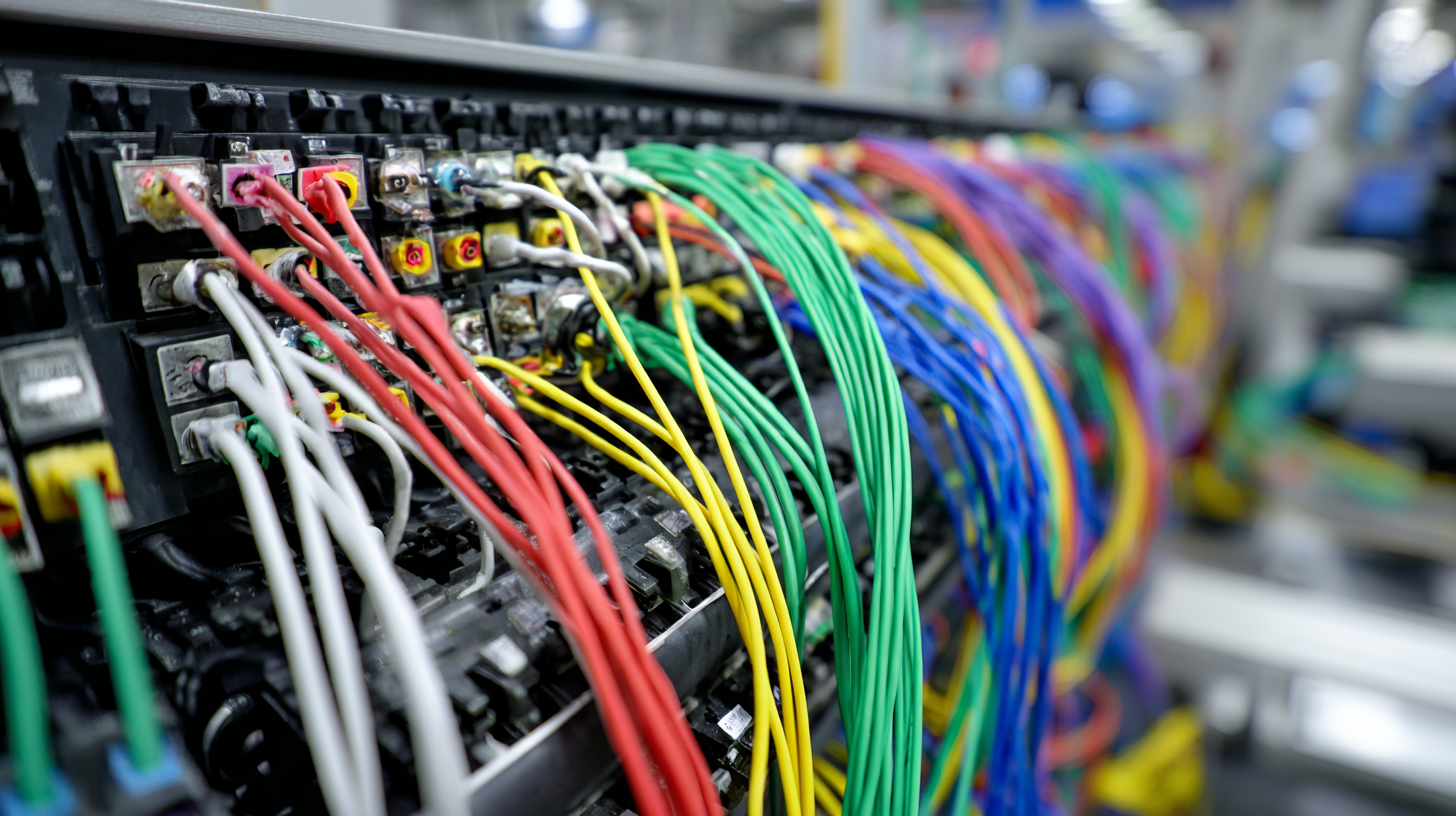

When evaluating wire harness manufacturing services for your project, several key factors should guide your decision. First, consider the manufacturer’s expertise and experience in your specific industry. A company that has worked with similar applications will likely understand the unique requirements and challenges, leading to better solutions tailored to your needs. Additionally, assess their production capabilities, including the technology and equipment used, as this can impact the overall quality and efficiency of the manufacturing process.

Quality control measures are another crucial aspect to review. Look for manufacturers that adhere to industry standards and certifications, as this indicates a commitment to producing reliable and high-quality products. Furthermore, it's important to evaluate their customer support and communication practices. A responsive and knowledgeable team can provide valuable insights and assistance throughout the project, ensuring that any concerns are promptly addressed. By carefully considering these factors, you can select a wire harness manufacturing service that aligns with your project requirements and expectations.

How to Choose the Right Wire Harness Manufacturing Service for Your Project

| Factor | Description | Importance Level | Considerations |

|---|---|---|---|

| Experience | Years in the industry and types of projects handled. | High | Look for a company with relevant experience in your industry. |

| Quality Standards | Compliance with industry certifications (e.g., ISO, UL). | High | Ensure they follow strict quality control processes. |

| Customization Capabilities | Ability to design wire harnesses to specific project requirements. | Medium | Check for flexibility in designs and modification processes. |

| Lead Time | Time required to manufacture and deliver the wire harness. | Medium | Assess their production capacity and scheduling efficiency. |

| Cost | Overall pricing structure for services offered. | High | Compare multiple quotes but beware of sacrificing quality for lower prices. |

| Technical Support | Availability of engineering support and expertise during manufacturing. | Medium | Evaluate their responsiveness and the level of support offered. |

Understanding Different Types of Wire Harnesses and Their Applications

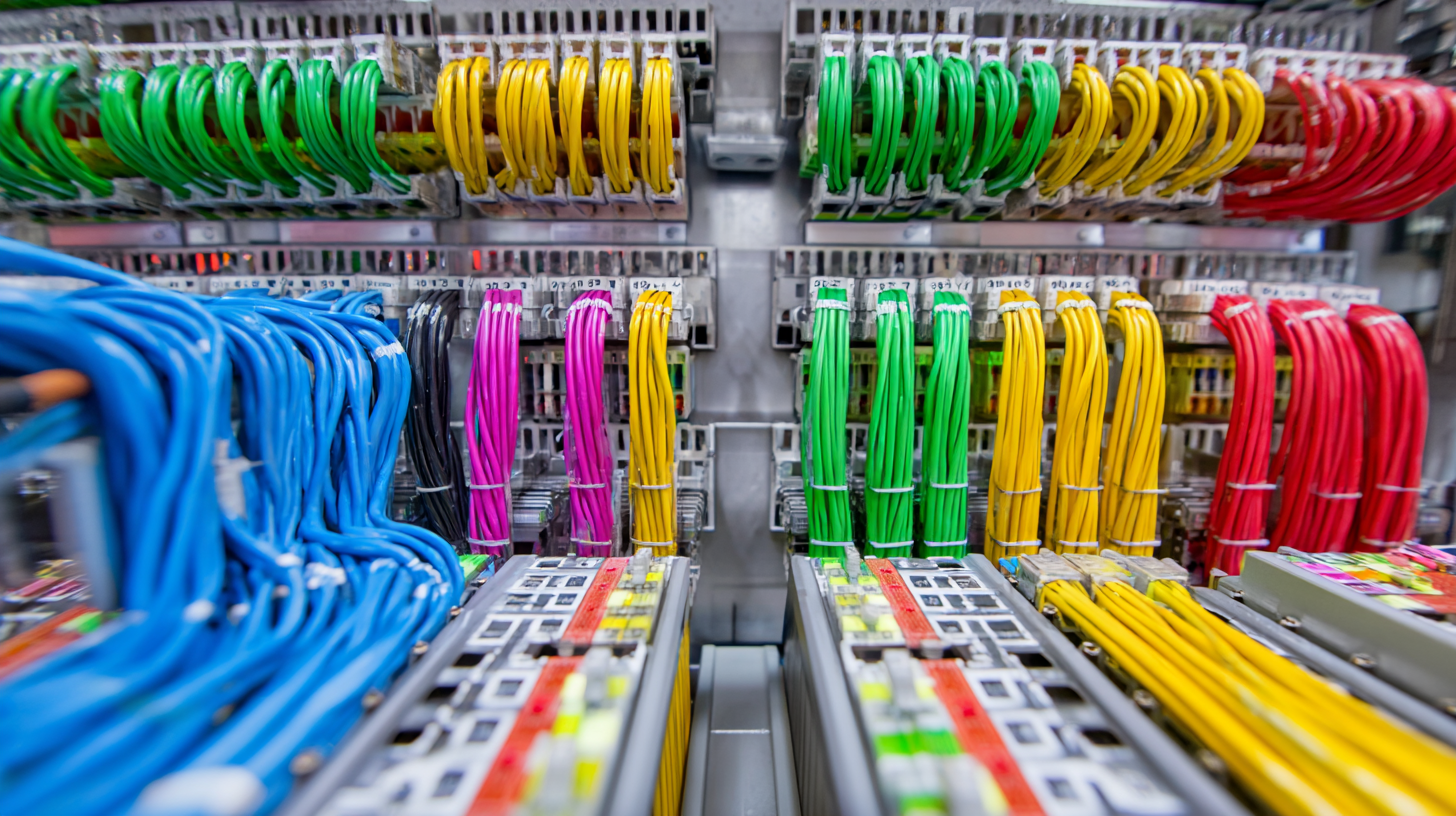

Wire harnesses play a critical role in many industries, from automotive to aerospace, each requiring specific types tailored to their unique applications. There are several types of wire harnesses, including the standard harness, which organizes multiple wires and cables into a single assembly, improving efficiency in installation and reducing the risk of errors. In automotive applications, this type often connects various engine components, electronic systems, and accessories, ensuring reliable performance under dynamic conditions.

Another type is the custom wire harness, designed for specialized applications where standard harnesses may not suffice. These harnesses can be tailored to accommodate particular specifications, including size, wiring patterns, and material choices. In industrial settings, custom harnesses are frequently used in machinery and equipment where precise connectivity is critical for operational safety and functionality. Understanding these different wire harness variations and their specific applications will help in selecting the right manufacturing service to meet project requirements effectively.

Types of Wire Harnesses and Their Applications

Key Industry Standards and Certifications for Quality Assurance

When selecting a wire harness manufacturing service for your project, understanding the key industry standards and certifications is crucial for ensuring quality assurance. The International Organization for Standardization (ISO) offers several important certifications, such as ISO 9001, which establishes a framework for maintaining consistent quality management systems. A 2022 report by Markets and Markets indicated that ISO-certified manufacturers demonstrate 20% more efficiency in production processes, significantly reducing the risk of defects and failures in wire harnesses.

In addition to ISO certifications, adherence to the Underwriters Laboratories (UL) standards is also essential. UL certification ensures that the wire harnesses meet safety and performance criteria, which are critical for applications in automotive, aerospace, and industrial sectors. According to the latest data from the National Electrical Manufacturers Association (NEMA), products compliant with UL standards are nearly 30% less likely to encounter safety-related recalls. By choosing a wire harness manufacturer with these certifications, project managers can enhance reliability and safety, ultimately leading to greater customer satisfaction and reduced liability risks.

Cost Analysis: Balancing Quality and Budget in Wire Harness Production

When selecting a wire harness manufacturing service, cost analysis becomes a crucial step in ensuring your project is delivered on time and within budget. According to a report by *Research and Markets*, the wire harness market is projected to reach $80 billion by 2024, with cost factors greatly influencing production decisions. Striking the right balance between quality and affordability can make or break your project's success. High-quality materials may come with higher upfront costs, but they often lead to improved durability and reduced failure rates, ultimately saving money in the long run.

**Tips:** Always request detailed quotes from various manufacturers to compare pricing structures effectively. Understanding the cost components—material, labor, and overhead—can help you identify where savings can be made without sacrificing quality.

Moreover, consider the importance of supplier relationships. According to *Market Insight Reports*, companies that maintain long-term partnerships with their suppliers often enjoy better pricing and priority service. This approach not only ensures consistency in product quality but can also reduce lead times and unexpected costs, enhancing your overall project efficiency.

**Tips:** Engage with potential manufacturers early in your project to gain insights into their capabilities and pricing strategies. Collaboration can lead to more favorable terms and a clearer understanding of the cost implications associated with various design choices.

The Importance of Communication and Collaboration with Manufacturers

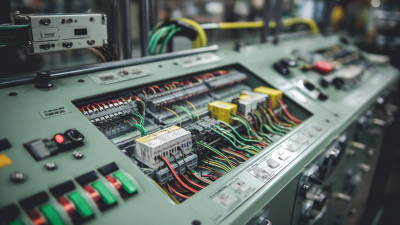

When selecting a wire harness manufacturing service, effective communication and collaboration with the manufacturer are crucial elements that can significantly impact the project's success. A clear dialogue allows for the exchange of ideas and requirements, ensuring that both parties are aligned in their objectives. Discussing specific technical specifications, design preferences, and timeline expectations upfront helps to establish a solid foundation for the project. This proactive approach can prevent misunderstandings later on, thereby minimizing delays and unexpected costs.

Collaboration extends beyond initial discussions; it involves ongoing engagement throughout the manufacturing process. Manufacturers who encourage feedback and inquiries foster an environment of trust and partnership. When clients feel comfortable discussing their concerns or asking for adjustments, the end product is more likely to meet or exceed expectations. Additionally, a collaborative relationship can lead to innovative solutions, as manufacturers may offer insights based on their expertise and experience, ultimately enhancing the wire harness's quality and functionality.

Related Posts

-

Innovative Examples of Best Wire Harness Manufacturing Practices in 2023

-

Unmatched Quality in Chinese Manufacturing of Wire Harness Solutions Now Gaining Global Popularity

-

How to Choose the Right Assembly Wire for Your Specific Project Needs

-

Essential Checklist for Choosing the Best Wire Harness Equipment for Your Production Line

-

How to Choose the Right Assembly Wire for Your Project Needs

-

Exploring Innovative Harness Wire Alternatives for Enhanced Connectivity Solutions

Toll Free: (888) 802-2505

Phone: (256) 845-1255 or (256) 845-4493

Fax: (256) 845-1321 or (256) 845-4468

© 2025 Heritage Wire Harness, LLC