Blog

How to Choose the Best Wire Harness Manufacturing Solutions for Your Needs

In the evolving landscape of wire harness manufacturing, making informed decisions about the right manufacturing solutions is crucial for businesses to thrive. As Michael Johnson, a renowned industry expert and CEO of WireTech Solutions, states, "Choosing the right wire harness manufacturing partner can make all the difference in ensuring product reliability and performance." This statement underscores the importance of selecting a manufacturing solution that aligns with specific operational needs and quality standards.

As industries increasingly demand customized wire harnesses designed for complex applications, companies must navigate a myriad of options available in the market. The selection process requires a careful assessment of factors such as production capabilities, technological advancements, and supplier reliability. Understanding these factors is essential for businesses aiming to optimize their production lines and maintain a competitive edge.

In this guide, we will explore the top 10 wire harness manufacturing solutions of 2025, breaking down critical elements to consider when making your choice. With insights from industry leaders and experts, we aim to equip you with the knowledge necessary to choose the best wire harness manufacturing solutions tailored to your unique requirements.

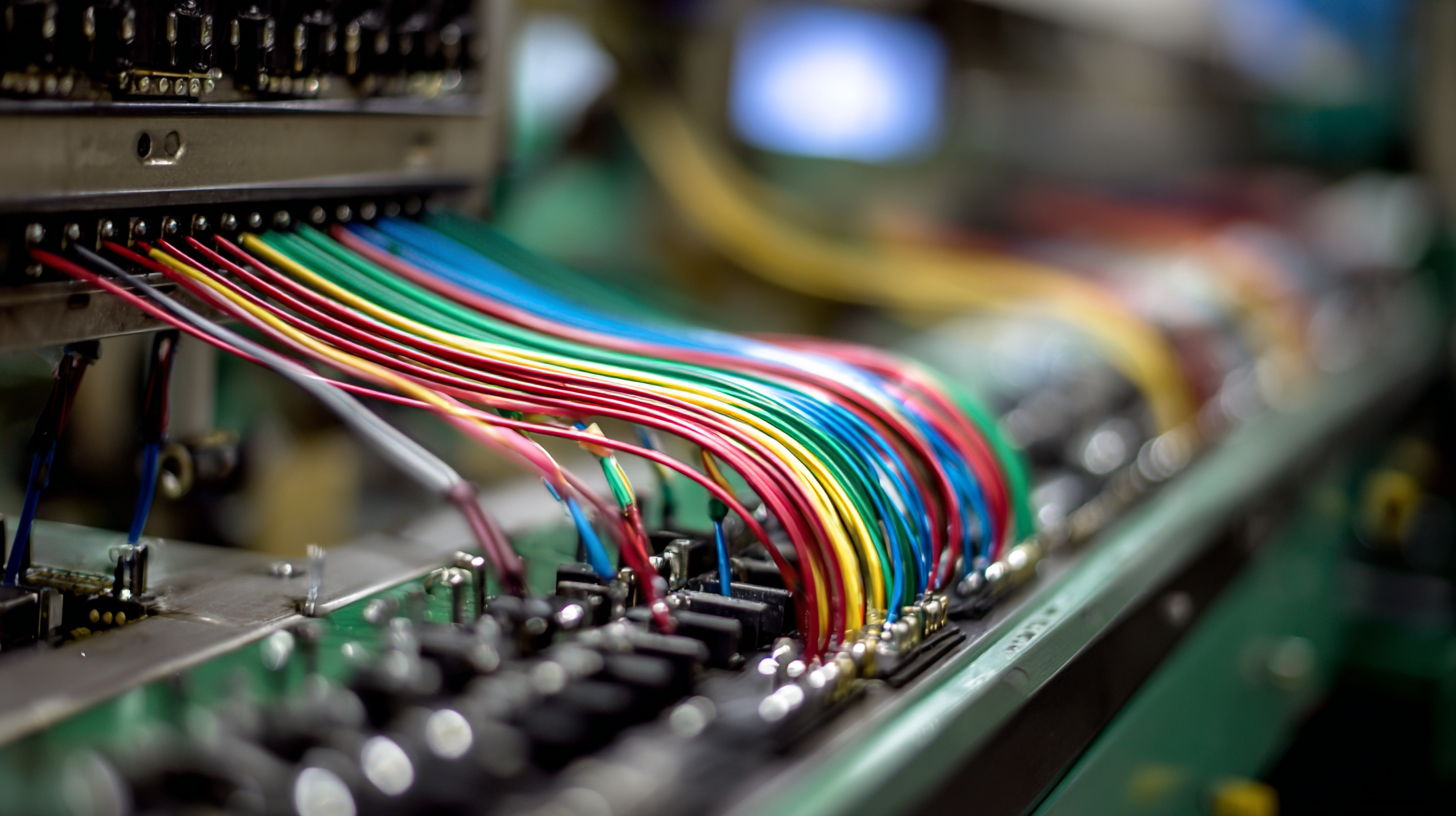

Understanding Wire Harness Types and Their Applications in Various Industries

Wire harnesses play a crucial role in various industries, acting as the central nervous system that connects multiple components and systems. With the growing focus on renewable energy and sustainable practices, there has been an increase in demand for specialized wire harness solutions tailored to these sectors. According to a report from MarketsandMarkets, the global wire harness market is projected to reach USD 56.2 billion by 2025, growing at a CAGR of 6.5% during the forecast period. This growth is significantly driven by advancements in renewable energy technologies such as solar, wind, and hydropower, which require dependable and efficient wiring systems to ensure optimal performance.

In the renewable energy sector, the use of wire harnesses must satisfy specific requirements such as durability, flexibility, and resistance to environmental factors. For instance, solar power installations necessitate wire harnesses capable of withstanding extreme temperatures and UV exposure, while wind energy applications often require designs that can endure severe weather conditions. The automotive industry, another major user of wire harnesses, is also evolving towards electric and hybrid vehicle technologies where lightweight and high-efficiency wiring is essential. As industries increasingly embrace sustainability, selecting the right wire harness manufacturing solutions tailored to these distinct applications becomes critical for maximizing efficiency and supporting growth in the renewable energy market.

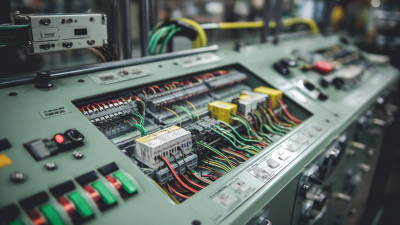

Evaluating Manufacturing Capabilities: Assessing Quality Standards and Certificates

When choosing the best wire harness manufacturing solutions, evaluating manufacturing capabilities becomes crucial. One of the primary aspects to consider is the quality standards adhered to by the manufacturer. It’s essential to look for certifications such as ISO 9001, which signifies a commitment to consistently delivering products that meet quality requirements. Manufacturers who hold such certifications often have stringent quality control processes in place, ensuring that each wire harness meets the necessary performance and safety standards.

Additionally, assessing the manufacturer's compliance with industry-specific standards can further guide your decision. For instance, if you require wire harnesses for automotive applications, certifications like IATF 16949 can indicate a manufacturer’s focus on quality and continuous improvement within the automotive sector. By examining these quality standards and certificates, you can gauge the reliability of the manufacturer and their ability to deliver products that not only meet your specific needs but also adhere to the highest industry benchmarks. This thorough evaluation helps in establishing a partnership with a manufacturer that aligns with your quality expectations and operational demands.

Quality Standards and Certificates in Wire Harness Manufacturing

Key Factors in Cost-Benefit Analysis for Wire Harness Solutions

When selecting wire harness manufacturing solutions, a thorough cost-benefit analysis is crucial. Key factors to consider include

material quality, manufacturing efficiency, and production scalability. High-quality materials may have a higher upfront cost but can significantly reduce long-term expenses due to lower failure rates and enhanced durability. Evaluating the supplier's production capabilities

will help ensure they can meet your evolving demands, thereby optimizing your investment.

Tips: Always request samples from potential suppliers to assess their material quality and craftsmanship. Conducting a small-scale test order can also reveal insights into their lead times and responsiveness,

important elements in your overall evaluation.

Another essential aspect is the supplier’s ability to provide customization options. A flexible manufacturing partner can adapt to specific design requirements without excessive costs, making your project more streamlined and effective. Comparing quotes will also reveal valuable insights

into market rates, so you can ensure you’re getting the best value for the specific features your project requires.

Tips: Consider using a scoring system to evaluate potential manufacturers based on factors like price, quality, capability, and customer service. This structured approach can facilitate more informed decision-making.

Exploring the Importance of Customization and Flexibility in Manufacturing

When selecting a wire harness manufacturing solution, customization and flexibility are paramount. The unique demands of various industries necessitate bespoke designs that can accommodate specific requirements. Custom wire harnesses allow businesses to create products that fit perfectly within their systems, enhancing overall functionality and efficiency. This tailored approach not only leads to better performance but also reduces the risks associated with using generic harnesses that may fall short in specialized applications.

Furthermore, flexibility in manufacturing processes is equally critical. As market needs evolve, the capacity to adapt production lines and designs swiftly becomes a significant advantage. Manufacturers that offer scalable solutions can respond promptly to changes in demand, ensuring minimal downtime and optimized resource allocation. This dynamic capability enables companies to stay competitive and innovative, paving the way for future growth while maintaining high standards of quality and reliability in their wire harness products.

Analyzing Supplier Reputation and Customer Feedback in Wire Harness Procurement

When selecting wire harness manufacturing solutions, analyzing supplier reputation and customer feedback is crucial. A supplier's reputation can provide insights into their reliability, quality, and overall capability to meet specific manufacturing needs. Companies often turn to industry reviews, testimonials, and ratings to gauge a supplier's performance. A well-established supplier with a positive track record is likely to maintain high standards and deliver products that align with expectations.

Customer feedback plays a significant role in the procurement process. By examining reviews and case studies from previous customers, potential buyers can assess how a manufacturer addresses challenges such as production timelines, quality assurance, and customer service. Engaging directly with past clients, if possible, can yield valuable insights into the responsiveness and support offered by the supplier. Prioritizing suppliers who value and act on customer feedback can enhance the likelihood of a successful procurement experience, ensuring that the wire harness solutions effectively meet the specific operational requirements of the business.

Related Posts

-

Revolutionizing Connectivity: The Future of Wire Harness Solutions for Emerging Technologies

-

Essential Checklist for Choosing the Best Wire Harness Equipment for Your Production Line

-

Unmatched Quality in Chinese Manufacturing of Wire Harness Solutions Now Gaining Global Popularity

-

Exploring Innovative Harness Wire Alternatives for Enhanced Connectivity Solutions

-

Innovative Techniques for Streamlined Wire Harness Production

-

Innovative Wire Harness Solutions Spotlighted at 2025 China 138th Canton Fair

Toll Free: (888) 802-2505

Phone: (256) 845-1255 or (256) 845-4493

Fax: (256) 845-1321 or (256) 845-4468

© 2025 Heritage Wire Harness, LLC