Blog

7 Essential Features of the Best Wire Harness Equipment for Optimal Efficiency

In the rapidly evolving landscape of manufacturing, the efficient production of wire harness equipment has become a key factor in ensuring optimal operational performance. According to a recent industry report by MarketsandMarkets, the global wire harness market is projected to reach $69.3 billion by 2025, driven by the increasing demand in sectors such as automotive, aerospace, and consumer electronics. This remarkable growth highlights the necessity for manufacturers to leverage advanced wire harness equipment that not only enhances productivity but also ensures high-quality output.

Implementing cutting-edge features in wire harness production can significantly reduce labor costs, minimize errors, and streamline workflow processes. As companies strive to remain competitive in this booming market, understanding the seven essential features of the best wire harness equipment is crucial for achieving sustained efficiency and innovation.

Key Characteristics That Define High-Quality Wire Harness Equipment

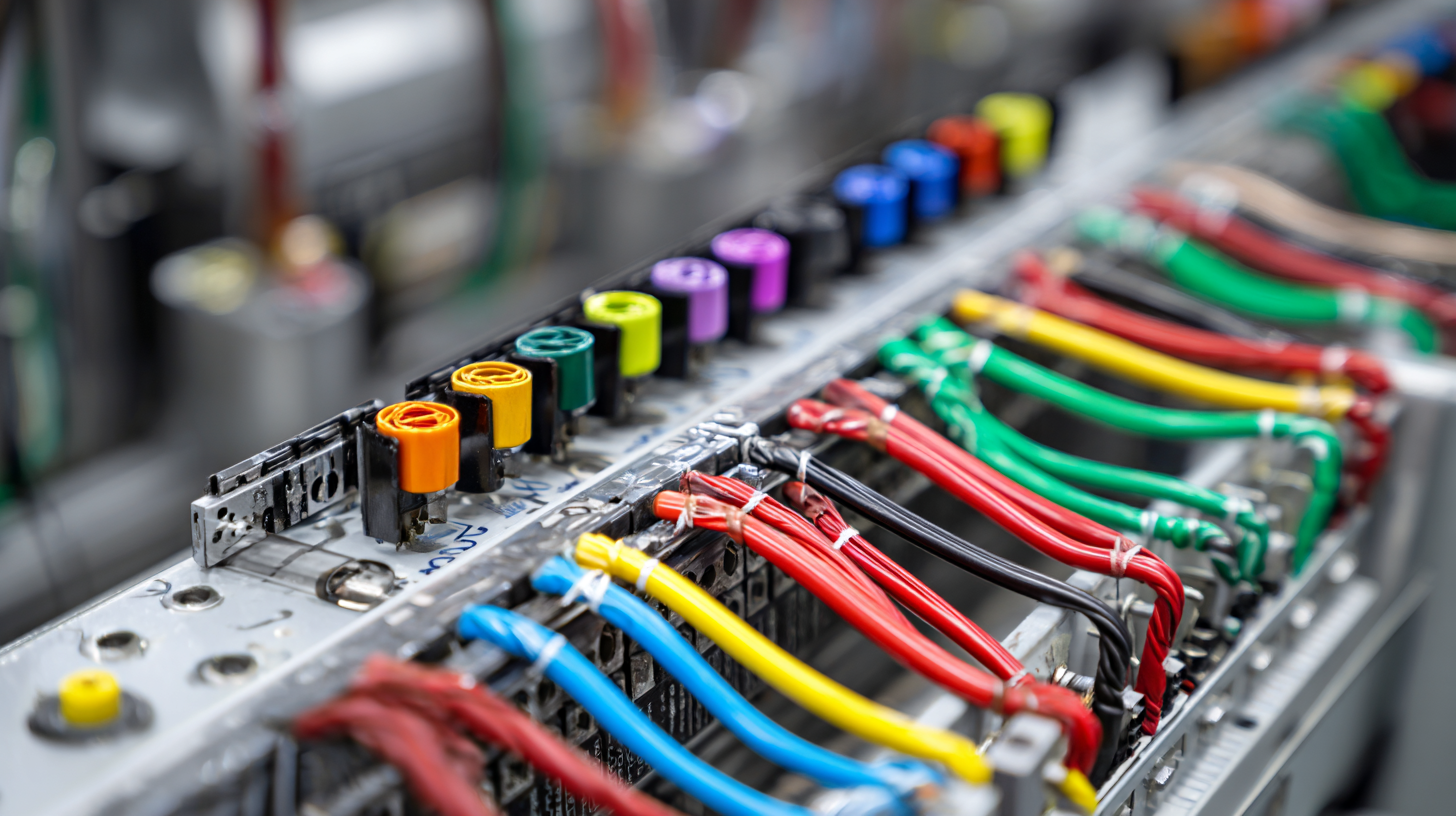

When selecting high-quality wire harness equipment, several key characteristics stand out that significantly enhance efficiency in production. First and foremost, precision is paramount. Equipment that offers high accuracy in cutting, stripping, and crimping wires ensures less rework and waste, contributing to a more streamlined manufacturing process. This precision not only leads to better product quality but also optimizes operational time, enabling businesses to meet tight deadlines without compromising standards.

Another essential feature is the adaptability of the equipment. High-quality wire harness machinery should be capable of accommodating various wire sizes and types, allowing for versatility in production. This adaptability not only supports diverse project requirements but also reduces downtime associated with equipment changeovers. Additionally, user-friendly interfaces and automation capabilities improve overall ease of use, minimizing the learning curve for operators and increasing productivity. Investing in wire harness equipment that embodies these attributes will undoubtedly drive optimal efficiency and meet the demands of modern manufacturing environments.

7 Essential Features of the Best Wire Harness Equipment for Optimal Efficiency

| Feature | Description | Benefits |

|---|---|---|

| Precision Cutting Tools | Tools designed for accurate wire cutting with minimal waste. | Increased efficiency and reduced material costs. |

| Ergonomic Design | Equipment designed to minimize strain and enhance user comfort. | Improved operator productivity and satisfaction. |

| Advanced Software Integration | Software solutions that support design, assembly, and tracking. | Streamlined processes and better data management. |

| Durable Material Construction | Use of high-quality materials for long-lasting performance. | Reduced frequency of equipment replacement. |

| Versatile Adaptability | Ability to adjust to different wire types and sizes. | Increased flexibility and application across projects. |

| Comprehensive Safety Features | Integrated safety mechanisms to protect users during operation. | Enhanced workplace safety and compliance. |

| Cost-Effectiveness | Equipment designed to offer high performance at a reasonable price. | Maximized return on investment for businesses. |

Innovative Technology Features for Enhanced Productivity in Wire Harnessing

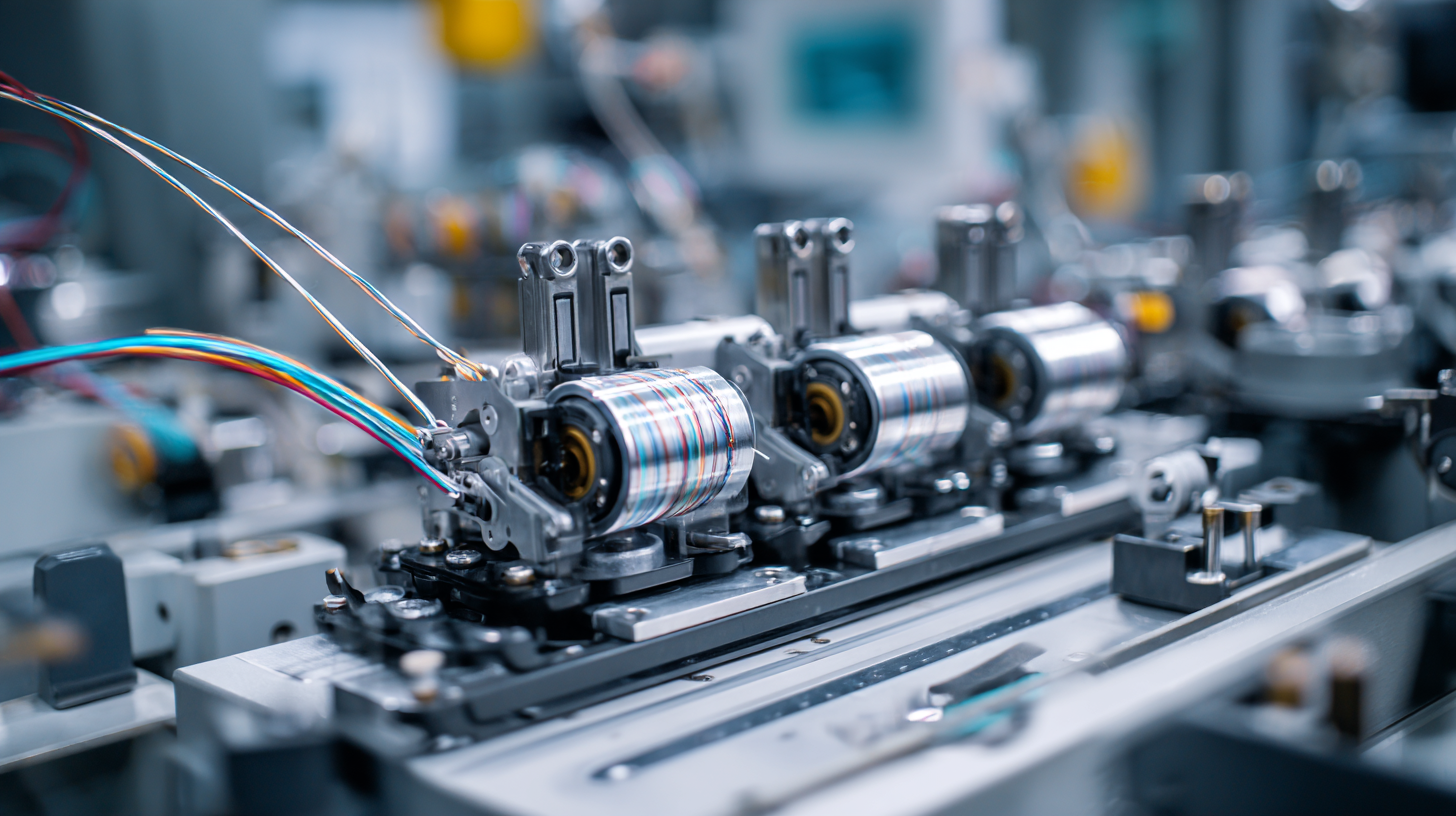

In the fast-evolving wire harness sector, innovative technology features play a crucial role in enhancing productivity. The integration of artificial intelligence in wire harness equipment is a game-changer, allowing for real-time data analysis and streamlined processes. With AI-driven machinery, manufacturers can optimize production schedules and reduce downtime, ultimately boosting efficiency. Furthermore, automation in wire harness assembly not only minimizes human error but also accelerates the overall production cycle.

Tips: To fully leverage these advancements, companies should invest in training their workforce to adapt to AI technologies, ensuring they understand the nuances of operating new equipment. Additionally, regular updates and maintenance of wire harness systems can prevent inefficiencies and maximize uptime. Keeping abreast of market trends and consumer demands is vital, as the wire harness market is projected to see substantial growth driven by factors such as rising automotive sales and AI integration.

By adopting cutting-edge features in wire harness equipment, businesses can stay ahead in a competitive landscape while driving productivity to new heights.

Efficiency Maximization: Ergonomics in Wire Harness Equipment Design

When it comes to wire harness equipment design, ergonomics plays a crucial role in enhancing operational efficiency. According to a 2022 report by the Ergonomics Society, workplaces that incorporate ergonomic principles can boost productivity by up to 25%. For wire harness manufacturing, this means designing equipment that minimizes strain and maximizes comfort for operators, leading to fewer work-related injuries and reduced downtime.

A key aspect of ergonomic design is the adjustment capabilities of equipment. Research from the Institute for Ergonomics indicates that adjustable workstations can lead to a 30% improvement in worker performance. By ensuring that all components of wire harness equipment, from the assembly jigs to the spooling machines, can be tailored to the user's needs, manufacturers can create a work environment that promotes fluid, efficient workflows. Additionally, intuitive interfaces and streamlined processes reduce cognitive load, allowing operators to focus on production rather than navigating complicated machinery.

Furthermore, incorporating ergonomic tools such as lightweight wire strippers and easily maneuverable trolleys can significantly reduce fatigue. A study published in the Journal of Occupational Health found that ergonomic tools improve not only worker satisfaction but can also lead to a decrease in errors by 15%. Ultimately, integrating ergonomics into wire harness equipment design is paramount for achieving optimal efficiency and fostering a healthier workplace.

Critical Safety Features to Look for in Wire Harnessing Tools

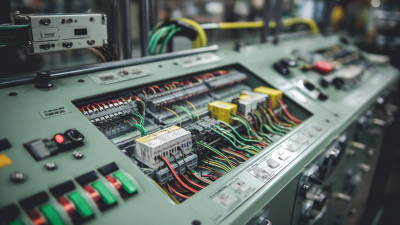

When selecting wire harnessing tools, safety should be at the forefront of your considerations. Critical safety features in wire harness equipment can mean the difference between a successful project and a potentially dangerous work environment. First and foremost, look for tools equipped with protective guards and insulated handles. These features prevent accidental cuts and electrical shocks, providing a safer working experience. Additionally, tools with automatic shut-off mechanisms can reduce the risk of overheating and damage during prolonged use, ensuring both the operator’s safety and the longevity of the equipment.

When selecting wire harnessing tools, safety should be at the forefront of your considerations. Critical safety features in wire harness equipment can mean the difference between a successful project and a potentially dangerous work environment. First and foremost, look for tools equipped with protective guards and insulated handles. These features prevent accidental cuts and electrical shocks, providing a safer working experience. Additionally, tools with automatic shut-off mechanisms can reduce the risk of overheating and damage during prolonged use, ensuring both the operator’s safety and the longevity of the equipment.

Ergonomics also play a vital role in the safety of wire harnessing tools. Tools that are designed with user comfort in mind can help minimize fatigue and the risk of repetitive strain injuries. Look for equipment that is lightweight, easy to handle, and features non-slip grips. Furthermore, it is essential that the tools comply with industry safety standards, offering peace of mind that they have been thoroughly tested and meet rigorous safety requirements. Incorporating these critical safety features not only enhances the efficiency of your wire harnessing tasks but also fosters a safer workplace environment.

Cost-Effectiveness: Balancing Quality and Budget in Wire Harness Equipment

When investing in wire harness equipment, achieving a balance between quality and budget is crucial for manufacturers aiming for optimal efficiency. According to a recent industry report by MarketsandMarkets, the global wire harness market is projected to reach $40 billion by 2027, with a significant push towards automated solutions that enhance production capabilities while controlling costs. Companies focusing on high-quality equipment can reduce long-term operational costs by minimizing downtime and maintenance, which is often a hidden expense in manufacturing.

Moreover, integrating advanced technologies such as automated cutting and crimping systems can initially seem expensive, but the return on investment is significant. The same report highlights that manufacturers utilizing automated equipment can increase production efficiency by up to 30%. Thus, while it may require a larger upfront investment, selecting reliable and efficient wire harness equipment ultimately leads to greater savings and improved product quality over time. By balancing these aspects effectively, companies can secure a competitive edge in the fast-evolving market landscape.

Cost-Effectiveness of Wire Harness Equipment

Related Posts

-

Innovative Examples of Best Wire Harness Manufacturing Practices in 2023

-

How to Choose the Right Cables Connections for Your Business Needs

-

How to Choose the Right Assembly Wire for Your Project Needs

-

Essential Checklist for Choosing the Best Wire Harness Equipment for Your Production Line

-

Ultimate Guide to Mastering Wire Cutting Techniques for Precision Engineering

-

Top Strategies for Optimizing Wire Assembly Processes for Maximum Efficiency

Toll Free: (888) 802-2505

Phone: (256) 845-1255 or (256) 845-4493

Fax: (256) 845-1321 or (256) 845-4468

© 2025 Heritage Wire Harness, LLC