Blog

Understanding the Importance of Wire Harness Solutions in Modern Technology

In today’s rapidly evolving technological landscape, wire harness solutions play a critical role across various industries, from automotive to aerospace and consumer electronics. As reported by the Global Wire Harness Market Analysis, the industry is expected to reach $83 billion by 2027, reflecting a compound annual growth rate (CAGR) of 6.5% from 2020. This growth underscores the increasing reliance on complex wire harness systems that ensure efficient connectivity and reliability in modern equipment. With the advancement of smart technologies and the Internet of Things (IoT), the demand for innovative wire harness solutions that can support high-speed data transmission and withstand harsh environments is more pressing than ever.

This article delves into the significance of wire harness solutions and their impact on enhancing operational efficiency, safety, and overall device functionality in contemporary applications.

The Role of Wire Harness Solutions in Connecting Modern Devices

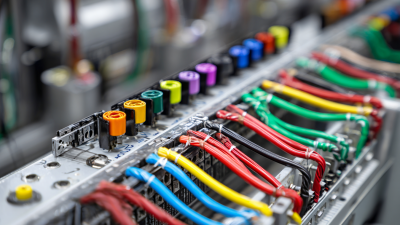

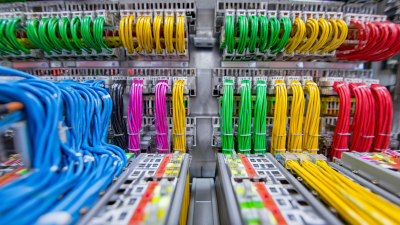

In today’s fast-paced technological landscape, wire harness solutions play a crucial role in connecting various modern devices. These intricate assemblies of wires and connectors not only streamline electrical connections but also enhance the overall performance and reliability of devices. From automotive systems to consumer electronics, wire harnesses reduce the complexity of wiring, allowing for more efficient manufacturing processes and simpler repairs.

**Tip:** When selecting wire harness solutions, consider the specific environment in which they will operate. Factors such as temperature, exposure to chemicals, and mechanical stress can significantly affect the durability and longevity of the harnesses.

Moreover, the versatility of wire harness solutions enables them to adapt to various applications across industries. They facilitate data transfer and power supply, ensuring seamless communication between devices. Effective wire harness designs can minimize electromagnetic interference, which is essential for maintaining the function of sensitive electronic components.

**Tip:** It's advisable to collaborate with experienced manufacturers who can provide custom wire harness solutions tailored to your specific needs, ensuring that the final product meets both technical specifications and industry standards.

Importance of Wire Harness Solutions in Modern Technology

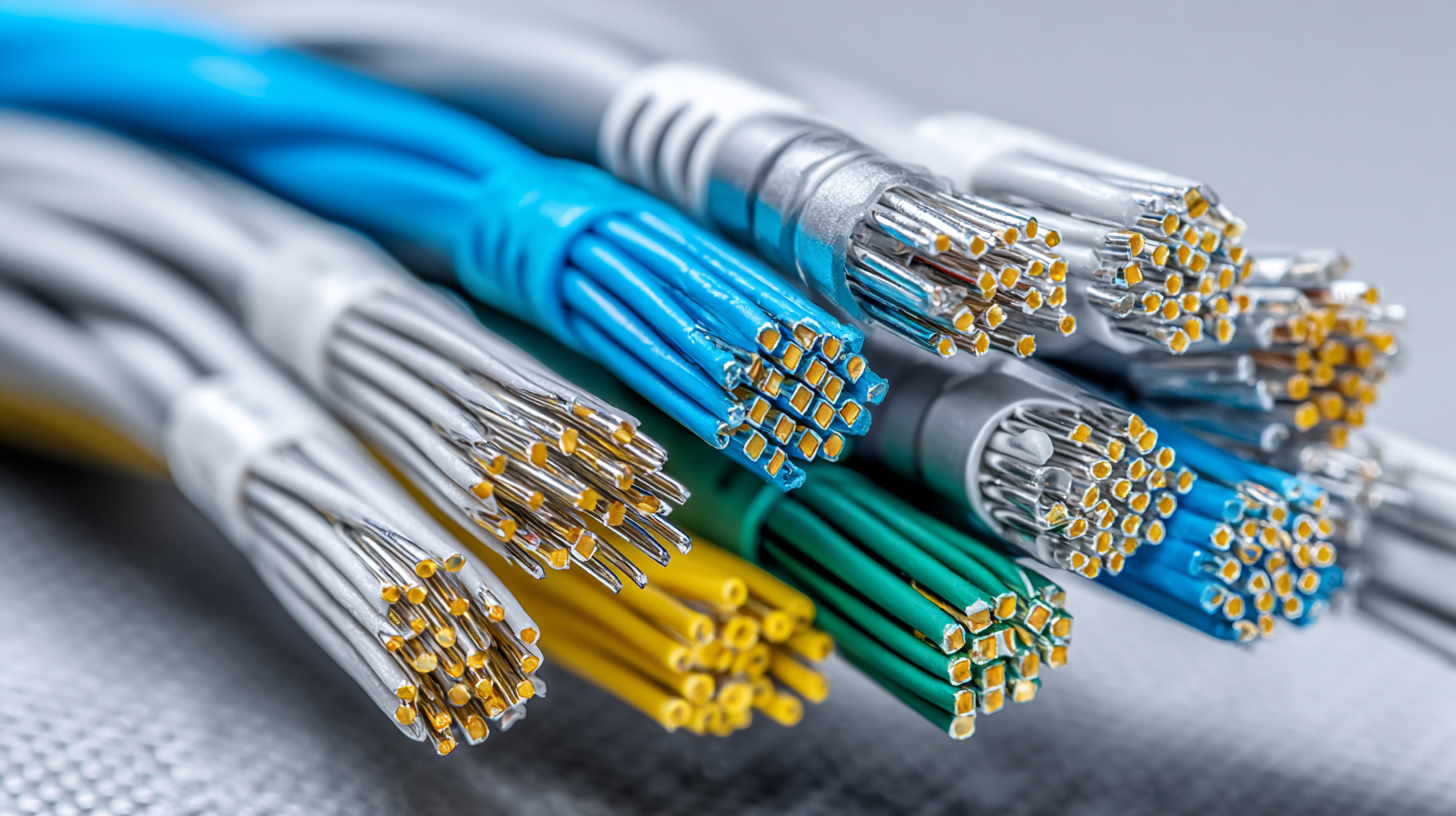

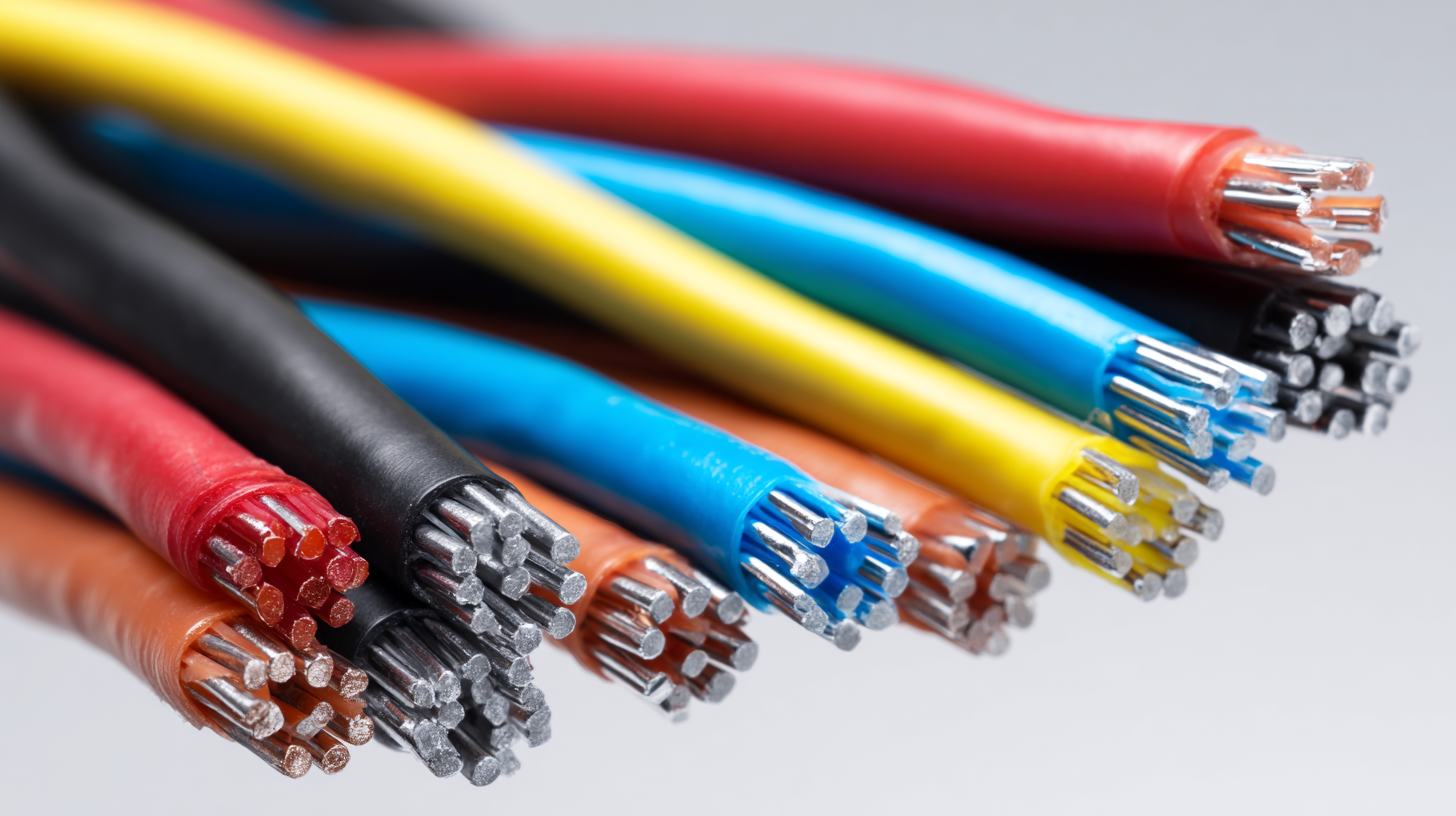

Key Components and Materials Used in Wire Harness Manufacturing

Wire harness manufacturing is a crucial aspect of modern technology, as it encompasses various key components and materials essential for effective electrical integration. At the heart of wire harnesses are conductors, typically made from copper or aluminum, due to their excellent conductivity and flexibility. These conductors are insulated with materials like PVC, Teflon, or rubber, which not only protect them from environmental factors but also ensure safety by preventing short circuits. The choice of insulation material often depends on the specific application and the operating environment, whether it's high temperatures, moisture, or chemical exposure.

In addition to conductors and insulation, connectors play a vital role in the wire harness assembly. These components facilitate secure electrical connections and enable easy disassembly for repairs or upgrades. Made from durable materials such as plastic or metal, connectors need to withstand mechanical stress while maintaining reliable performance. Furthermore, the integration of protective coverings like conduits and sleeves enhances the longevity of wire harnesses by safeguarding against abrasion and impacts. The combination of high-quality materials and precise manufacturing processes ensures that wire harness solutions meet the rigorous demands of modern technology, from automotive systems to consumer electronics.

Applications of Wire Harness Solutions Across Various Industries

Wire harness solutions play a critical role in various industries, significantly contributing to the seamless operation of modern technology. In sectors such as automotive, renewable energy, and industrial automation, wire harnesses facilitate efficient power distribution and signal transmission. With the growing focus on renewable energy sources like solar, wind, and hydropower, the demand for high-quality wire harnesses is on the rise. These applications not only enhance system reliability but also support sustainable practices, positioning wire harness solutions as a vital component in future technological advancements.

Tips: When selecting wire harness solutions, consider the specific requirements of your application, including environmental conditions and electrical load. Evaluate suppliers based on their ability to provide custom designs that meet your precise needs, ensuring durability and reliability.

As industries transition to more automated processes and embrace Industry 4.0, the complexity of systems has increased, driving the demand for sophisticated wire harness solutions. The market for wire harnesses is projected to reach $165.2 billion by 2034, reflecting this trend. Companies must leverage innovative designs and cutting-edge materials to stay competitive in this evolving landscape.

Tips: Regularly review the latest technologies and trends in wire harness manufacturing to ensure your systems remain efficient and up-to-date. Collaborating with experts in the field can also yield insights that enhance your product offerings and operational efficiency.

Advantages of Custom Wire Harness Design for Technology Innovation

In today's fast-paced technological landscape, custom wire harness design has emerged as a vital component for driving innovation. These tailored solutions enable manufacturers to streamline their products while enhancing performance and reliability. By designing wire harnesses that meet specific requirements, businesses can ensure optimal electrical connectivity, reduce installation time, and lower overall production costs. Custom wire harnesses provide the flexibility needed to adapt to rapidly changing technologies, ensuring compatibility with various devices and systems.

**Tip 1:** When considering a custom wire harness, involve a team of engineers early in the design process. Their insights can help identify potential challenges and optimize your harness layout for better efficiency.

Moreover, custom wire harnesses contribute significantly to the durability of electronic devices. By utilizing high-quality materials and precise manufacturing techniques, these wire solutions are built to withstand environmental stresses, such as temperature fluctuations and mechanical vibrations. This resilience not only extends the lifespan of the products but also enhances user safety and satisfaction.

**Tip 2:** Always prioritize quality over cost when selecting materials for your wire harness. Investing in durable components can save money in the long run by reducing the need for repairs or replacements.

Future Trends in Wire Harness Solutions and Their Impact on Tech Development

The future of wire harness solutions is poised for significant evolution, driven by advancements in technology and the increasing need for efficiency in various industries. As the demand for compact and lightweight electronic devices grows, manufacturers are turning to innovative wire harness designs that not only optimize space but also enhance performance. The integration of smarter materials, such as flexible printed circuits and advanced insulation, is expected to revolutionize how wire harnesses function within complex assemblies, allowing for greater adaptability in diverse applications.

Moreover, the rise of automation and smart manufacturing practices is influencing the development of wire harness solutions. Companies are now emphasizing the incorporation of sensors and diagnostics within wire harnesses, enabling real-time monitoring and predictive maintenance. This trend not only boosts operational efficiency but also contributes to reducing downtime and improving product lifespan. As industries such as automotive and aerospace focus on electrification and connectivity, the role of wire harness solutions will become increasingly critical, highlighting their importance in shaping the future of technological development.

| Dimension | Current Trends | Future Predictions | Impact on Technology |

|---|---|---|---|

| Material Innovation | Use of lightweight and durable materials | Increased adoption of sustainable materials | Improved efficiency in manufacturing processes |

| Integration with IoT | Growing connectivity in wire harnesses | Enhanced smart technology integration | Greater functionality and communication in devices |

| Automation in Production | Use of robotics in assembly | Full automation of wire harness production | Reduced production costs and time |

| Customization Options | Tailored solutions for various industries | Increased demand for bespoke designs | Enhanced compatibility across technologies |

| Safety Features | Focus on fire-resistant and protective materials | Smart harnesses with self-diagnostic abilities | Improved safety in automotive and aerospace applications |

Related Posts

-

Innovative Wire Harness Solutions Spotlighted at 2025 China 138th Canton Fair

-

Innovative Examples of Best Wire Harness Manufacturing Practices in 2023

-

Unmatched Quality in Chinese Manufacturing of Wire Harness Solutions Now Gaining Global Popularity

-

7 Essential Features of the Best Wire Harness Equipment for Optimal Efficiency

-

How to Choose the Right Wire Harness Manufacturing Service for Your Project

-

Revolutionizing Connectivity: The Future of Wire Harness Solutions for Emerging Technologies

Toll Free: (888) 802-2505

Phone: (256) 845-1255 or (256) 845-4493

Fax: (256) 845-1321 or (256) 845-4468

© 2025 Heritage Wire Harness, LLC