Blog

Unveiling Wire Cutting Techniques: A Comprehensive Study on Precision and Innovation in Manufacturing

As industries continue to evolve, the demand for precision in manufacturing has never been greater, particularly in fields such as electronics and aerospace, where the quality of components can significantly affect performance and safety. According to a recent report by Market Research Future, the global wire cutting market is projected to reach USD 1.5 billion by 2025, driven by technological advancements and the need for higher accuracy in production processes.

Wire cutting, a method that utilizes electrically conductive materials to slice through various substrates, has emerged as a vital technique in achieving dimensional accuracy and minimizing material waste. This comprehensive study aims to unveil the intricate techniques behind wire cutting, exploring innovations that bolster efficiency and effectiveness in manufacturing.

By delving into the latest technologies and methodologies, we seek to highlight the critical role wire cutting plays in shaping the future of precision engineering.

Understanding Wire Cutting Techniques: Importance in Modern Manufacturing

Wire cutting techniques are pivotal in modern manufacturing,

playing a crucial role in the precision and efficiency of production processes. These techniques, including

electrical discharge machining (EDM) and laser cutting,

have undergone significant innovations, enabling manufacturers to achieve tighter tolerances and reduce waste.

As industries strive for higher accuracy in components, understanding the intricacies of

wire cutting becomes essential for staying competitive in the evolving landscape.

Wire cutting techniques are pivotal in modern manufacturing,

playing a crucial role in the precision and efficiency of production processes. These techniques, including

electrical discharge machining (EDM) and laser cutting,

have undergone significant innovations, enabling manufacturers to achieve tighter tolerances and reduce waste.

As industries strive for higher accuracy in components, understanding the intricacies of

wire cutting becomes essential for staying competitive in the evolving landscape.

Moreover, the integration of advanced technologies such as CNC machining further enhances the effectiveness of wire cutting methods. CNC machines allow for automated control, which not only increases production speed but also ensures consistency across various manufacturing runs. Coupled with the rise of automation and robotics, the future of wire cutting techniques appears to be on a transformative path, enhancing manufacturing capabilities and meeting the demands of increasingly complex semiconductor packaging and other precision-driven industries. Embracing these advancements is key for manufacturers aiming to capitalize on new opportunities in the marketplace.

Key Factors Influencing Precision in Wire Cutting Processes

Wire cutting techniques have significantly evolved, driven by the demand for precision in manufacturing processes. Several key factors influence the precision of wire cutting, including the type of wire material, the cutting method employed, and the machine calibration. Selecting the correct type of wire, whether it's copper, steel, or aluminum, can optimize the performance and accuracy of the cutting process. Additionally, advanced methods like electrical discharge machining (EDM) allow for intricate cuts that are often unattainable with traditional techniques.

Tips: Always consider the tolerance levels required for your specific application. When using EDM, ensure that the machine is regularly calibrated to maintain cutting accuracy. Proper maintenance of cutting tools and machines can also prevent wear and tear, leading to improved results over time.

Another crucial factor in influencing precision is the environment in which the cutting takes place. Factors such as temperature, humidity, and cleanliness can impact the final results. A controlled environment minimizes unwanted variables that could distort the cutting outcomes.

Tips: Invest in environmental controls if your facility faces fluctuations in temperature or humidity. Keeping the workspace clean and organized can greatly enhance operational efficiency and precision in wire cutting tasks.

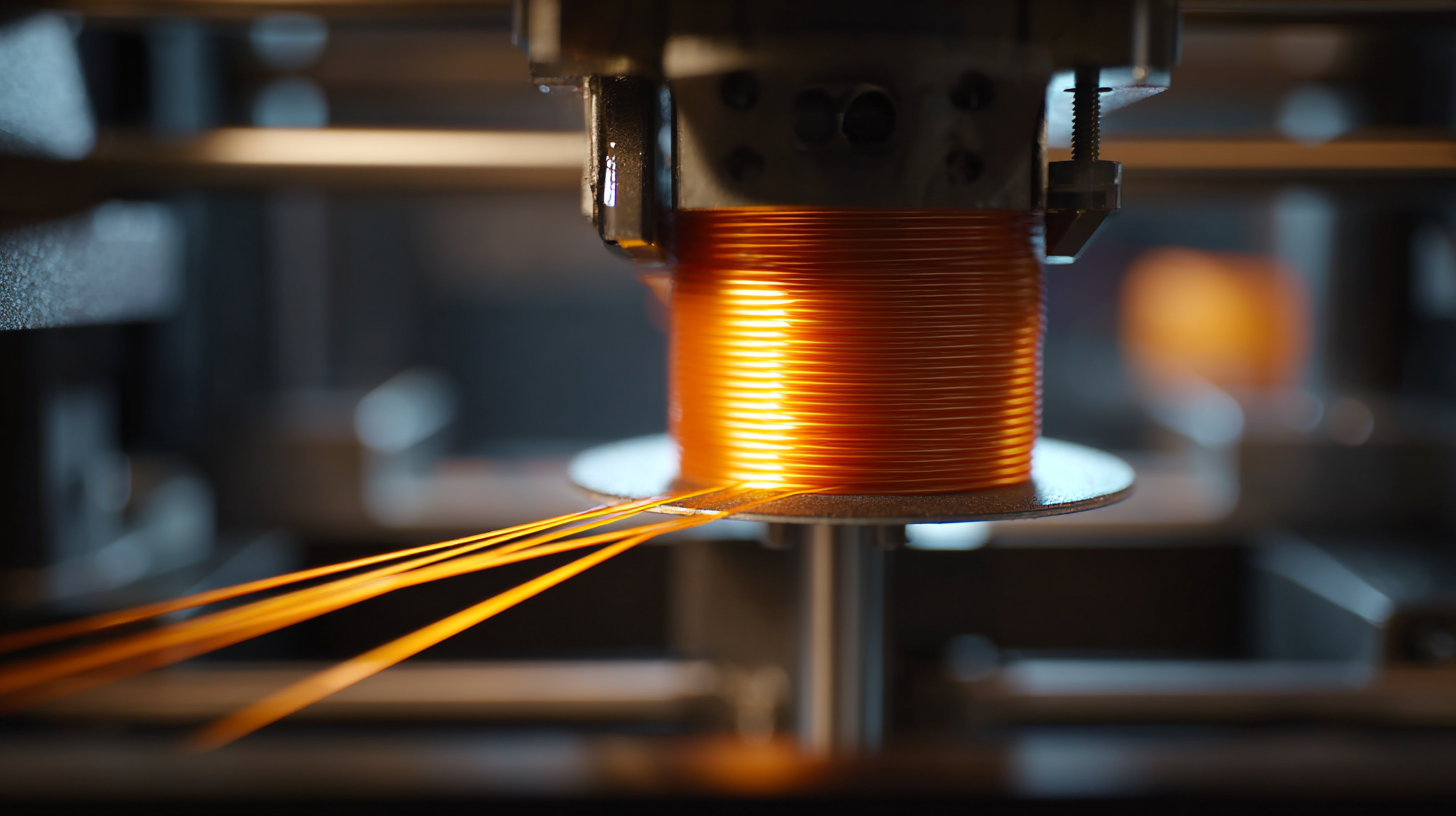

Innovative Technologies Revolutionizing Wire Cutting Methods

The realm of wire cutting has witnessed significant advancements, thanks to innovative technologies that are transforming methods previously deemed conventional. One major breakthrough is the adoption of laser cutting technology, which offers unparalleled precision and efficiency. By utilizing focused laser beams, manufacturers can create intricate designs with minimal material loss. This not only enhances the quality of the final product but also reduces operational costs associated with traditional cutting methods.

Furthermore, the integration of automation and robotics into wire cutting processes is revolutionizing production lines. Automated wire cutting machines equipped with advanced software can optimize cutting patterns and enhance consistency, thereby minimizing human error. Additionally, these innovations facilitate faster turnaround times, allowing manufacturers to respond swiftly to market demands. As the industry continues to evolve, it's clear that embracing these cutting-edge technologies is essential for achieving excellence in wire cutting manufacturing.

Innovative Technologies in Wire Cutting Methods

Comparative Analysis of Traditional vs. Advanced Wire Cutting Techniques

The evolution of wire cutting techniques has significantly transformed manufacturing processes, with a

critical examination needed to understand the distinctions between

traditional and advanced methods. Traditional wire cutting often relies on mechanical means, such as saws

or shears, which can be effective but may lack the precision required for intricate designs. These older

methods typically struggle with material limitations and can produce irregular edges, affecting the overall

quality of the finished product.

The evolution of wire cutting techniques has significantly transformed manufacturing processes, with a

critical examination needed to understand the distinctions between

traditional and advanced methods. Traditional wire cutting often relies on mechanical means, such as saws

or shears, which can be effective but may lack the precision required for intricate designs. These older

methods typically struggle with material limitations and can produce irregular edges, affecting the overall

quality of the finished product.

In contrast, advanced wire cutting techniques leverage technology such as laser cutting, water jet cutting, and electrical discharge machining (EDM).

These modern techniques provide unparalleled precision and versatility,

allowing manufacturers to work with a variety of materials and geometries. Laser cutting, for instance,

produces clean edges with minimal kerf, making it ideal for detailed applications. The comparative analysis

reveals that while traditional methods may still hold relevance in simple tasks, advanced techniques are

increasingly essential for industries demanding high precision and innovation, illustrating a clear shift

towards more sophisticated solutions in wire cutting.

Future Trends in Wire Cutting: Integrating Automation and AI

The future of wire cutting technologies is being shaped significantly by the integration of automation and artificial intelligence (AI). As the electrical discharge machining (EDM) market continues to evolve, projections indicate robust growth, with trends suggesting a diversification of applications across various sectors, including aerospace and automotive. According to industry reports, the EDM market size is expected to expand considerably by 2032, driven by advancements in precision techniques such as micro EDM and rapid hole drilling, which cater to increasingly demanding manufacturing processes.

The SIAF Guangzhou Industrial Automation Exhibition illuminates the critical role of industrial robotics in realizing the future of intelligent manufacturing. The event, scheduled for March 10 to 12, showcases core technologies that enhance efficiency and precision in production environments. As manufacturers adopt more intelligent distribution systems and standard distribution boards, the confluence of automation and advanced wire cutting techniques will be paramount. This not only optimizes operational workflows but also underscores the importance of adapting to future trends that prioritize innovation and precision in manufacturing processes.

Related Posts

-

Understanding the Importance of Wire Harness Solutions in Modern Technology

-

Harness Solutions Shaping Industry Trends at the 2025 China Import and Export Fair

-

Comparing Harness Wires: Selecting the Optimal Option for Your Electrical Needs

-

Unlocking Efficiency: How Harness Solutions Can Boost Productivity by 30% in Manufacturing

-

7 Essential Features of the Best Wire Harness Equipment for Optimal Efficiency

-

How to Choose the Right Assembly Wire for Your Specific Project Needs

Toll Free: (888) 802-2505

Phone: (256) 845-1255 or (256) 845-4493

Fax: (256) 845-1321 or (256) 845-4468

© 2025 Heritage Wire Harness, LLC