Blog

Why Is Wire Harness Manufacturing Critical for Industries?

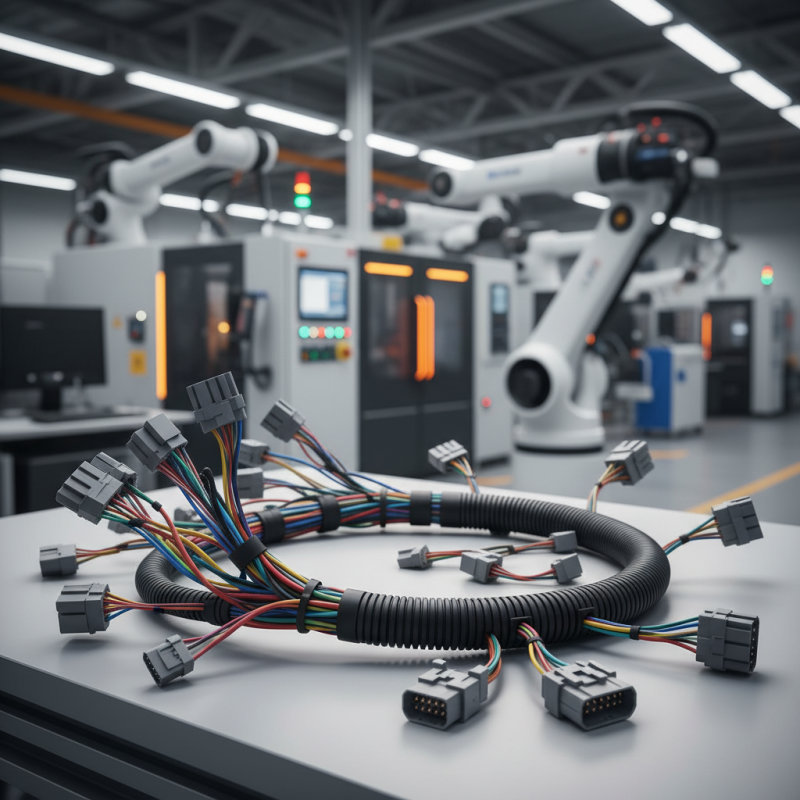

Wire harness manufacturing plays a vital role in various industries. This process assembles numerous wires and connectors into a single unit. It helps streamline electrical connections in vehicles, appliances, and machinery. Without efficient wire harnesses, systems may fail or become less reliable.

The significance of wire harness manufacturing goes beyond mere assembly. Quality and precision are essential for safety and functionality. A poorly made harness can lead to malfunctions, impacting productivity and user safety. Therefore, industries must focus on high standards and reliable materials.

However, challenges persist in wire harness manufacturing. Balancing cost, quality, and complexity is no easy task. Manufacturers must navigate tight deadlines while ensuring that every harness meets specifications. This requires constant reflection and improvement to maintain a competitive edge.

Understanding Wire Harness Manufacturing and Its Importance

Wire harness manufacturing plays a vital role in various industries, including automotive, aerospace, and telecommunications. According to a recent report by Markets and Markets, the global wire harness market is projected to reach $154.6 billion by 2026, growing at a CAGR of 5.5%. This growth reflects the increasing complexity of electrical systems and the rising demand for reliable, high-quality connections.

The importance of wire harnesses lies in their ability to manage electrical connections efficiently. A well-designed wire harness ensures that different components communicate effectively, reducing the risk of failure. In automotive production, for instance, wire harnesses are essential for vehicle safety and functionality. The average car contains about 1,500 wires, making quality manufacturing critical. Failure in this area can lead to severe consequences, potentially endangering lives.

However, challenges remain. Many manufacturers grapple with quality control issues and production inefficiencies. The industry faces significant pressure to reduce costs while maintaining high standards. A report from Allied Market Research notes that around 30% of wire harness failures are linked to poor manufacturing practices or design flaws. This highlights the need for continuous improvement and innovation in wire harness production processes. Addressing these issues is crucial for the future of wire harness manufacturing and its impact on various industries.

Key Industries Utilizing Wire Harnesses in Their Operations

Wire harnesses play an essential role in various industries. They serve as the

nervous system, connecting different components efficiently.

The automotive industry is a prime example. Here, wire harnesses streamline electrical systems.

Vehicles require numerous wires for lights, sensors, and entertainment systems.

A poorly designed harness can lead to

failures or malfunctions.

Another key sector is aerospace. Wire harnesses support complex avionics systems.

They ensure the safe functioning of aircraft, where reliability is critical.

Manufacturers face strict regulations. Mistakes can be costly—both financially and

in terms of safety. Even minor errors in wiring can lead to

dire consequences.

The renewable energy industry also relies on wire harness technology. It connects

solar panels to inverters and storage systems. Engineers must address unique

challenges like exposure to the elements. Proper insulation and durability are vital.

With rapid growth in this field, the demand for

innovative wire harness solutions is increasing.

This constant evolution invites both opportunities and reflections on best practices.

Components and Materials Involved in Wire Harness Production

Wire harness manufacturing plays a vital role in various industries. The components and materials used are crucial to the overall efficiency and safety of electrical systems. Typically, a wire harness consists of electrical wires, connectors, and insulation materials. According to industry reports, the global wire harness market is projected to reach $75 billion by 2026. This growth reflects rising demand across sectors such as automotive, aerospace, and consumer electronics.

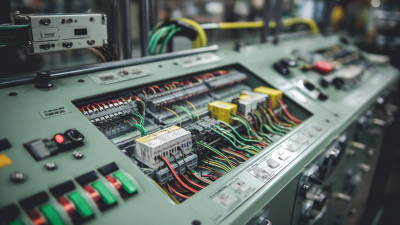

The materials utilized in wire harness production are diverse. Copper is the dominant choice for electrical conductivity. However, manufacturers are increasingly using aluminum due to cost and weight advantages. Insulation materials vary too, with PVC and cross-linked polyethylene being popular. Interestingly, some producers have started exploring bio-based materials as part of sustainability efforts. This shift raises questions about performance and longevity, needing further exploration.

Despite advances, challenges remain in wire harness production. Quality control can be inconsistent, leading to failures in crucial applications. Manufacturers must invest in better testing technologies. Accurate data collection during production is essential but often neglected. This oversight can result in flawed harnesses, with potential safety implications. Continuous improvement is necessary to address these gaps and meet industry standards effectively.

Why Is Wire Harness Manufacturing Critical for Industries? - Components and Materials Involved in Wire Harness Production

| Component | Material | Function | Industry Use |

|---|---|---|---|

| Wires | Copper, Aluminum | Conduct electrical signals | Automotive, Aerospace |

| Connectors | Plastic, Metal | Join electrical circuits | Consumer Electronics, Telecommunications |

| Insulation | PVC, XLPE | Prevent short circuits | Industrial Equipment, Robotics |

| Terminals | Brass, Nickel | Terminate wires | Aerospace, Medical Devices |

| Harness | Various Materials | Organize wiring system | Automotive, Marine |

The Process of Wire Harness Manufacturing: Steps and Techniques

Wire harness manufacturing is essential for many industries, notably automotive, aerospace, and electronics. This process starts with design and prototyping. Engineers create layouts, determining wire types and connectors needed. In 2022, the global wire harness market was valued at approximately $108 billion. Demand continues to soar. Yet, many manufacturers still struggle with outdated techniques.

Next comes assembly, where skilled workers meticulously group wires, ensuring proper length and organization. Specialized tools, such as crimping machines, play a vital role. Quality control cannot be overlooked. Reports show that around 10% of produced harnesses face defects. This leads to costly delays and dissatisfaction.

Testing is the final step. Harnesses undergo rigorous checks for insulation integrity and electrical continuity. Inconsistent testing protocols plague some companies. This inconsistency can result in severe safety risks. As industries evolve, so must the methods—adapting to technological advancements is critical.

Wire Harness Manufacturing: Key Factors and Their Impact

The chart above illustrates the critical factors impacting wire harness manufacturing, rated on a scale from 1 to 10. These dimensions highlight the importance of material quality, skilled labor, production efficiency, testing and quality control, and cost management in the manufacturing process.

Challenges and Innovations in Wire Harness Manufacturing Today

Wire harness manufacturing faces significant challenges today. As industries evolve, the demand for more complex wiring solutions grows. Innovative designs are essential but require precise engineering. Companies often struggle to keep up with rapid technological changes. Tight deadlines add further pressure, leading to occasional mistakes. Quality assurance becomes more critical as the stakes rise.

Moreover, sustainability is a pressing issue. Manufacturers must find eco-friendly materials without sacrificing performance. This transition can feel overwhelming, especially for smaller companies. Upgrading machinery and processes is a financial burden. Embracing new technologies, like automation, presents both opportunities and obstacles. Businesses must adapt quickly to stay competitive while mastering these advancements.

Amid these hurdles, there are opportunities for innovation. Companies are experimenting with new manufacturing techniques. For example, 3D printing can reduce waste and improve accuracy. Collaborations between engineers and designers foster creative solutions to current problems. Investing in workforce training is also vital. Skilled workers can drive progress and implement new ideas effectively.

Related Posts

-

2026 How to Choose the Right Wire Harness Wire for Your Project?

-

Innovative Techniques for Streamlined Wire Harness Production

-

Unmatched Quality in Chinese Manufacturing of Wire Harness Solutions Now Gaining Global Popularity

-

Exploring Innovative Harness Wire Alternatives for Enhanced Connectivity Solutions

-

Innovative Examples of Best Wire Harness Manufacturing Practices in 2023

-

Essential Checklist for Choosing the Best Wire Harness Equipment for Your Production Line

Toll Free: (888) 802-2505

Phone: (256) 845-1255 or (256) 845-4493

Fax: (256) 845-1321 or (256) 845-4468

© 2025 Heritage Wire Harness, LLC