Blog

How to Choose the Right Assembly Wire for Your Specific Project Needs

Choosing the right assembly wire is crucial for ensuring the success of your specific project needs, whether you're working on an electronic build, an automotive application, or a complex industrial setup. With the vast array of options available—varying in material, gauge, insulation type, and flexibility—making an informed decision can be daunting. This guide aims to simplify the selection process by highlighting key factors to consider when choosing assembly wire.

From understanding the electrical and thermal requirements to evaluating the mechanical properties and environmental conditions, each aspect plays a vital role in the overall performance and reliability of your project. By the end of this discussion, you will have a clear understanding of how to match the characteristics of assembly wire with your unique demands, ensuring optimal functionality and longevity in your applications.

Understanding Different Types of Assembly Wires Available in the Market

When selecting the right assembly wire for your specific project needs, it's essential to understand the variety of assembly wires available in the market. Different types of wires are designed for distinct applications, and their specifications can significantly impact the performance and reliability of your project. Common types include solid wire, stranded wire, and specialty wires such as high-temperature or high-flex options. Solid wire provides excellent conductivity and is suitable for permanent installations, while stranded wire is more flexible and ideal for applications requiring movement or bending.

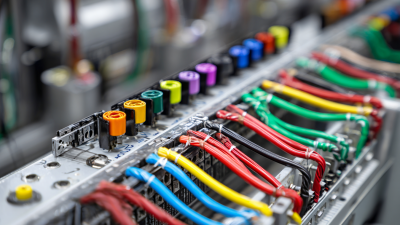

Another important consideration is the wire gauge and insulation type, which vary based on the project's electrical load and environmental conditions. Thicker gauges can handle higher currents, while insulation types, such as PVC or Teflon, provide varying degrees of protection against heat and chemicals. Additionally, understanding industry standards and certifications, such as UL or CSA ratings, ensures that you choose an assembly wire that meets safety and performance requirements for your specific application, ultimately leading to a successful project outcome.

How to Choose the Right Assembly Wire for Your Specific Project Needs

| Wire Type | Recommended Use | Gauge Range | Material | Cost per Foot |

|---|---|---|---|---|

| Solid Wire | General purpose wiring | 12-18 AWG | Copper | $0.10 |

| Stranded Wire | Flexible applications | 14-22 AWG | Copper | $0.15 |

| Tinned Copper Wire | Corrosion resistance | 12-24 AWG | Tinned Copper | $0.18 |

| Silicone Insulated Wire | High temperature applications | 16-30 AWG | Copper | $0.25 |

| Aluminum Wire | Lightweight applications | 10-14 AWG | Aluminum | $0.08 |

Identifying Project Requirements: Voltage, Current, and Insulation Needs

When selecting the appropriate assembly wire for your project, understanding your specific requirements regarding voltage, current, and insulation is critical. As the demand for energy-efficient solutions grows, particularly in the electronics sector, it is essential to recognize how advancements in materials like silicon carbide (SiC) and gallium nitride (GaN) influence wire selection. These materials have gained attention for their superior performance in high-voltage and high-current applications, which can directly affect the type of assembly wire you choose.

Furthermore, the focus on power semiconductors is shaping how industries approach their wiring needs. Projects that involve inverters and converters are increasingly relying on wires that can handle higher power loads while offering excellent thermal and electrical insulation. Identifying these parameters will help ensure that the wire used meets the operational demands and safety standards for your specific application. Thus, careful assessment of voltage ratings, current capacities, and compatible insulation materials is integral to optimizing your project's overall efficiency and reliability.

Evaluating Environmental Factors Affecting Wire Selection

When selecting assembly wire for specific project needs, evaluating environmental factors is crucial to ensure optimal performance and longevity of the wire. The operating environment can significantly influence wire selection, as different materials and insulation types respond distinctively to conditions such as temperature, humidity, and exposure to chemicals. For instance, in high-temperature settings, wires made from materials like Teflon or silicone may be necessary to prevent degradation, while in humid environments, corrosion-resistant materials are essential to maintain conductivity and reduce the risk of failure.

Additionally, consider the presence of mechanical stress, vibrations, or potential exposure to harsh industrial environments. In scenarios involving movement or flexing, flexible wires with robust insulation can mitigate wear and tear. For projects exposed to harsh chemicals or outdoor elements, choosing wires specifically rated for such conditions will not only enhance safety but also extend the service life of the assembly. By comprehensively assessing these environmental factors, project managers can make informed decisions that align wire characteristics with specific operational demands.

Comparing Cost and Quality: Balancing Budget and Performance

When selecting assembly wire for your project, it’s crucial to balance cost and quality effectively. High-grade wire often comes with a higher price tag, but it can significantly enhance the performance and longevity of your assembly. Investing in premium materials can lead to improved conductivity, reduced resistance, and increased durability under various stress conditions. This is essential for projects where reliability is paramount, as a failure in the wire could result in costly downtime and repairs.

On the other hand, budget constraints cannot be overlooked. While it may be tempting to opt for the cheapest option, a thorough assessment of the wire’s specifications and performance ratings is vital. Sometimes, lower-cost wires may not provide adequate insulation or could be prone to breakage, ultimately leading to greater expenses. A balanced approach involves evaluating the project’s specific requirements and determining which attributes—such as gauge, material type, and insulation quality—are non-negotiable. By carefully weighing your options, you can ensure that you achieve a balance between cost efficiency and quality performance.

Ensuring Compliance with Industry Standards and Regulations

When selecting assembly wire for specific projects, ensuring compliance with industry standards and regulations is paramount. With various types of wires available, understanding the relevant compliance requirements significantly influences the selection process. These standards are designed to guarantee safety, reliability, and performance, preventing potential issues that may arise from using substandard materials. For instance, adherence to national or international standards, such as those related to electrical conductivity or material durability, ensures that the wire can perform under intended conditions without risking failure.

Additionally, recent developments in the regulatory landscape emphasize the importance of compliance in modern industry practices. With new regulations being implemented, such as those surrounding non-banking payment institutions, it is essential for companies to stay updated on legal requirements that govern the use of assembly wires. This not only mitigates legal risks but also enhances the reputation and credibility of businesses in a competitive market. Companies must conduct thorough research and engage with industry experts to navigate these complexities, ensuring that the chosen materials meet both technical specifications and regulatory mandates.

Related Posts

-

Top Strategies for Optimizing Wire Assembly Processes for Maximum Efficiency

-

Exploring Innovative Harness Wire Alternatives for Enhanced Connectivity Solutions

-

7 Essential Features of the Best Wire Harness Equipment for Optimal Efficiency

-

Innovative Techniques for Streamlined Wire Harness Production

-

Innovative Examples of Best Wire Harness Manufacturing Practices in 2023

-

How to Choose the Right Assembly Wire for Your Project Needs

Toll Free: (888) 802-2505

Phone: (256) 845-1255 or (256) 845-4493

Fax: (256) 845-1321 or (256) 845-4468

© 2025 Heritage Wire Harness, LLC