Blog

2026 How to Choose the Right Wire Harness Wire for Your Project?

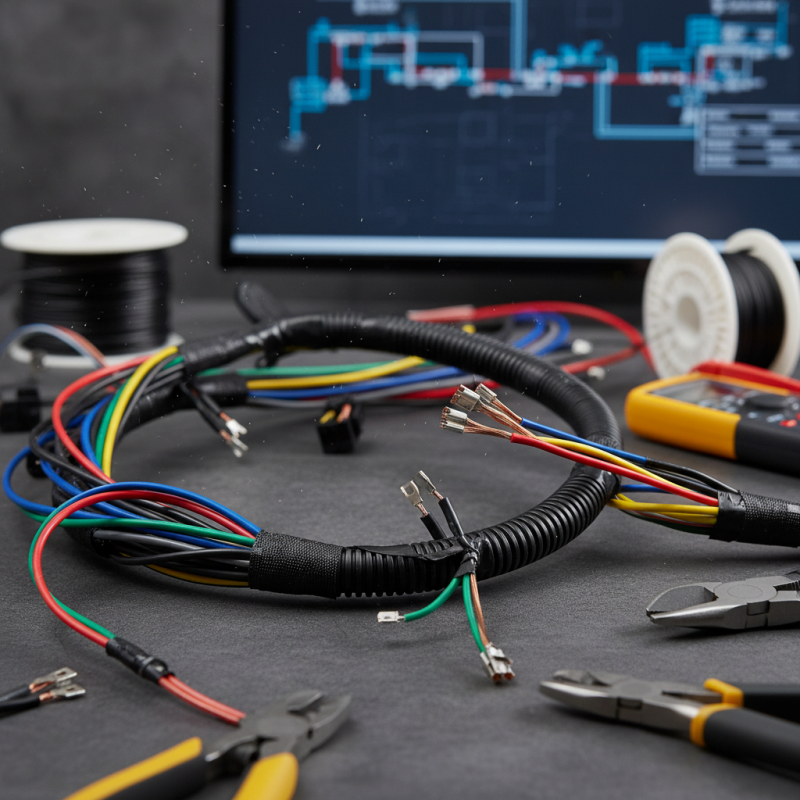

When embarking on a project that requires a wire harness wire, making the right choice can be daunting. Industry expert John S. Mitchell often states, "Selecting the correct wire is crucial for your project's success." His insight resonates deeply within the engineering community, where precision matters.

Wire harness wires come in various types, each designed for specific applications. Clear specifications are essential. Factors such as gauge, insulation type, and resistance play significant roles. Understanding these details can impact the performance and longevity of the entire system.

Many people overlook the importance of quality. Using subpar materials can lead to failures and costly repairs. Potential issues may arise from incorrect wire selection. It’s essential to weigh options carefully and avoid rushing into decisions. In the end, reflect on how wire harness wire choices can define the outcome of a project.

Understanding the Basics of Wire Harness Wire Types

When choosing wire for a harness, it’s essential to understand various types. Copper wires are common due to their excellent conductivity. They are flexible and easy to work with. However, they can corrode over time. This might lead to future issues. Aluminum wires are lighter but less conductive. They can work well in specific applications but lack durability.

Another aspect to consider is insulation. PVC, for example, is cost-effective and widely used. It handles heat but may not be the ideal choice for high-temperature environments. Then there are silicone-coated wires. These can endure higher temperatures and are flexible. Still, they come with added costs. Finding the right balance between cost and performance is crucial.

Think about the project requirements. Will the wires endure harsh conditions? What about mechanical stress? All these factors complicate choices. Each type has pros and cons. Mistakes can be costly to fix later. Take time to weigh options properly. Understanding your project's unique needs will guide you in making an informed decision.

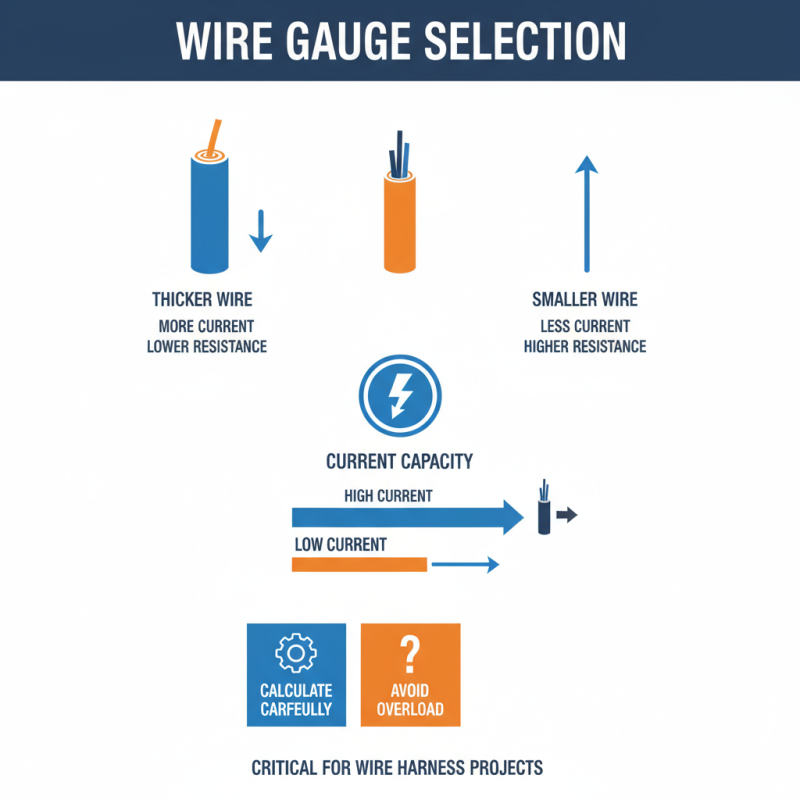

Factors to Consider When Selecting Wire Gauge for Your Project

Choosing the right wire gauge is a critical aspect of your wire harness project. The wire gauge affects how much current the wire can handle. Thicker wires conduct more current and have lower resistance. For lower current applications, a smaller gauge works. However, be mindful of your calculations.

Consider the distance the wire needs to travel. Longer distances can lead to voltage drops. Using a thicker wire can mitigate this issue. For example, if you’re powering a device farther from the power source, think twice about using a thinner wire. It might seem sufficient at first, but it could cause problems down the line.

Don’t overlook environmental factors. Wires exposed to heat or moisture need special consideration. That can change your gauge choice entirely. It's crucial to assess your project's specific requirements carefully. Mistakes in selection can lead to inefficient performance. Reflect on your needs and revisit your choices periodically.

Evaluating Insulation Materials for Wire Harness Applications

Choosing the right insulation material for a wire harness is crucial. It affects the performance and durability of your project. Various materials are available, each with unique benefits and drawbacks. PVC, for example, is affordable and versatile, but may not withstand extreme temperatures. On the other hand, options like silicone offer superior heat resistance but can be pricier.

When evaluating insulation materials, consider environmental factors. Exposure to chemicals, moisture, or UV light can degrade insulation. Polyethylene can resist moisture well but may not hold up against harsh chemicals. Assess the specific conditions your wire harness will face. It’s essential to test different materials in real-world scenarios. What works perfectly in theory may fail under stress.

Don’t overlook the importance of flexibility and size. Bulkier materials can hinder installation. Your design may require tight bends and curves. Ensure the insulation can accommodate those needs. Balancing these factors can be challenging. Each choice carries consequences. Take the time to analyze how different materials align with your project goals. Overall, this careful evaluation can help ensure a successful outcome.

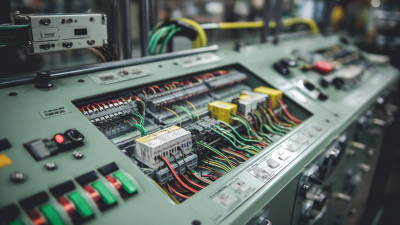

Assessing Environmental Conditions for Optimal Wire Harness Performance

When choosing the right wire harness wire, one crucial factor is the environmental conditions. Temperature and humidity can greatly affect wire performance. Extreme heat may cause insulation to degrade quickly. Cold temperatures might make the wire more brittle. Each project has its own unique challenges that can impact wire choice.

In addition to temperature, consider exposure to chemicals. Some wires can corrode when in contact with certain substances. For instance, oils or solvents may damage insulation over time. Choosing a wire that can withstand these conditions is essential. This often requires thorough assessment and reflection on the environment where the wire will be used.

It’s easy to overlook these factors during the planning phase. However, taking time to evaluate conditions can prevent future issues. A wire harness that fails in the field can lead to costly repairs. Make sure to gather information on the environmental factors that will affect your project. This step is often underestimated, yet is critical for long-term success.

2026 How to Choose the Right Wire Harness Wire for Your Project? - Assessing Environmental Conditions for Optimal Wire Harness Performance

| Wire Type | Temperature Rating (°C) | Humidity Resistance (%) | Chemical Resistance | UV Resistance |

|---|---|---|---|---|

| PVC Insulated Copper | -20 to 70 | 90 | Low | Moderate |

| XLPE Insulated Copper | -40 to 90 | 95 | High | High |

| Silicone Insulated Wire | -60 to 200 | 85 | Moderate | Very High |

| Teflon Insulated Wire | -60 to 260 | 80 | Very High | High |

| Nylon Coated Wire | -40 to 100 | 88 | Moderate | Moderate |

Regulatory Standards and Compliance for Wire Harness Wires

When selecting wire harness wires, understanding regulatory standards is crucial. Various industries have specific compliance requirements. For instance, the automotive sector often adheres to ISO 26262 for functional safety. This standard ensures that wiring systems can withstand operational challenges. Non-compliance can lead to safety hazards or product recalls.

Consider the electrical performance. According to a report by the International Electrotechnical Commission, improper wiring may cause up to 40% of electrical failures in vehicles. Choosing wires that meet relevant standards can mitigate this risk. The environment plays a role too. For instance, wires must be insulated properly to withstand temperatures and moisture levels. Meeting these parameters can be a challenge.

While many manufacturers claim compliance, inspecting certifications is vital. Not all wires labeled as compliant meet stringent standards, leading to potential project failures. Regular audits and testing help ensure quality. Thus, selecting the right wire harness consistently requires more diligence than many expect.

Related Posts

-

Innovative Techniques for Streamlined Wire Harness Production

-

Essential Checklist for Choosing the Best Wire Harness Equipment for Your Production Line

-

Unmatched Quality in Chinese Manufacturing of Wire Harness Solutions Now Gaining Global Popularity

-

Comparing Harness Wires: Selecting the Optimal Option for Your Electrical Needs

-

Exploring Innovative Harness Wire Alternatives for Enhanced Connectivity Solutions

-

Innovative Harness Assembly Solutions for Enhanced Efficiency and Performance

Toll Free: (888) 802-2505

Phone: (256) 845-1255 or (256) 845-4493

Fax: (256) 845-1321 or (256) 845-4468

© 2025 Heritage Wire Harness, LLC