Blog

Exploring Innovative Harness Wire Alternatives for Enhanced Connectivity Solutions

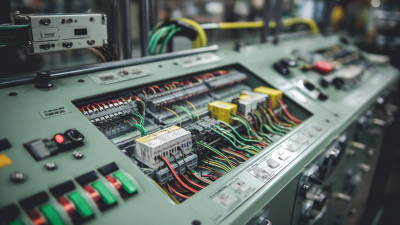

As technology continues to evolve at a rapid pace, the demand for efficient and reliable connectivity solutions has never been greater. One crucial component in enabling these solutions is the harness wire, which plays a significant role in transmitting power and data within various electronic systems. However, traditional harness wires often come with limitations, such as bulkiness, susceptibility to electromagnetic interference, and potential for signal degradation. This blog delves into innovative alternatives to conventional harness wire, exploring cutting-edge materials and design strategies that promise enhanced performance and flexibility. By understanding the reasons behind these advancements, we aim to highlight the benefits of adopting such alternatives in order to meet the growing needs of modern connectivity. From improved durability to greater efficiency, the exploration of these harness wire alternatives opens up new possibilities for industries ranging from automotive to telecommunications, paving the way for a more interconnected future.

Innovative Materials in Harness Wire: Transforming Connectivity Solutions

The evolution of harness wire materials is pivotal to enhancing connectivity solutions in various industries, particularly within the automotive sector. As vehicles become increasingly reliant on sophisticated electronics and software, the need for innovative materials in harness wiring becomes more pressing. These advancements are not just about improving connectivity; they are about enabling the entire ecosystem of automotive technology to function more optimally. Traditional materials may no longer suffice as vehicles transition to smart technologies and increased digital integration.

In light of these trends, manufacturers are exploring alternatives that offer better performance, such as lightweight composites and flexible conductive materials. These innovative solutions aim to reduce weight while enhancing electrical efficiency and durability. With software architecture driving the next wave of automotive innovation, the right harness materials will play a crucial role in creating a stable and high-performing ecosystem, allowing automakers to differentiate themselves in the competitive landscape of the 'Roaring 2020s'. This shift underscores the importance of rethinking not just the wiring but the entire approach to automotive connectivity solutions.

The Advantages of Fiber Optics Over Traditional Harness Wires

As industries strive for higher performance and efficiency, the debate between traditional harness wires and advanced fiber optic solutions has gained momentum. Fiber optics offer significant advantages, particularly in terms of bandwidth, speed, and durability. According to the Fiber Optic Association, fiber optic cables can transmit data at speeds up to 100 Gbps, vastly outpacing conventional copper wires that typically deliver speeds around 1 Gbps. This leap in performance is crucial for sectors like telecommunications and data centers, where high-speed connectivity is paramount.

Moreover, fiber optics are not just faster; they are also more reliable and immune to electromagnetic interference, making them ideal for environments with heavy machinery or electronic devices. A report by MarketsandMarkets indicates that the global fiber optic components market is projected to grow from $8.7 billion in 2020 to $16.3 billion by 2025, demonstrating a clear industry shift towards adopting these advanced materials. This trend highlights the ongoing demand for enhanced connectivity solutions that can support the increasingly data-driven landscape we navigate today.

Exploring Conductive Polymers: A Game Changer for Connectivity

Conductive polymers are emerging as a transformative solution in the field of connectivity, especially when integrated into biohybrid devices. Recent advances in this technology allow for seamless interactions between electronics and biological systems, paving the way for revolutionary healthcare applications. According to a report from the International Journal of Polymer Science, the market for conductive polymers is expected to reach over $5 billion by 2026, reflecting a compound annual growth rate of nearly 10% driven by innovations in healthcare and electronics.

In addition to healthcare, the application of conductive polymers extends to agriculture, where innovations like "electric soil" have shown significant promise. Researchers have observed that integrating conductive materials into soil can enhance crop production and plant growth by up to 50% within just 15 days. This is particularly relevant in the context of increasing agricultural demands driven by climate change and limited resources. The ability of conductive polymers to facilitate efficient nutrient and water transport in plants demonstrates their multi-disciplinary versatility and potential impact on both connectivity solutions and sustainable practices.

The Role of Wireless Technologies in Reducing Harness Wire Dependency

In recent years, the automotive industry has witnessed a significant shift towards wireless technologies, particularly in the realm of harness wire alternatives. The advent of advanced wireless systems is reshaping how vehicles are designed and built, offering unprecedented flexibility and efficiency. For instance, the introduction of a groundbreaking wireless battery management system (BMS) for electric vehicles exemplifies this trend. By reducing the need for traditional wiring harnesses by an astonishing 90%, this technology not only streamlines the manufacturing process but also enhances overall vehicle performance.

Wireless technologies play a vital role in minimizing dependency on conventional harness wiring, making vehicles lighter and more reliable. This reduction in wiring complexity directly translates to decreased costs and increased design versatility. With fewer components to manage, manufacturers can innovate more freely and implement features that enhance safety and user experience. As the industry continues to embrace these advancements, the potential for wireless solutions to revolutionize connectivity will only grow, setting the stage for a new era of automotive engineering.

Chart: Exploring Innovative Harness Wire Alternatives

Sustainability in Harness Wire Alternatives: Benefits for the Environment

As industries strive for greater sustainability, the exploration of innovative harness wire alternatives has become crucial. Traditional harness wires made from copper and aluminum contribute to significant environmental issues, including resource depletion and pollution. According to a report by the International Wire and Cable Trade Association, approximately 12 million tons of copper are mined annually, leading to substantial ecological degradation. In contrast, emerging alternatives such as bio-based materials and recycled metals present an opportunity to mitigate these environmental impacts.

Sustainability benefits not only the planet but also bolsters industry resilience. For instance, a study by the Sustainable Energy Authority estimates that using recycled materials can reduce greenhouse gas emissions by up to 70% compared to virgin materials. Additionally, manufacturers embracing eco-friendly harness wire solutions report lower production costs and enhanced brand loyalty from increasingly environmentally conscious consumers. By prioritizing sustainable practices, the industry can pave the way for future innovation that aligns profit with responsibility, ultimately contributing to a healthier ecosystem.

Related Posts

-

Unmatched Quality in Chinese Manufacturing of Wire Harness Solutions Now Gaining Global Popularity

-

Essential Checklist for Choosing the Best Wire Harness Equipment for Your Production Line

-

Ultimate Guide to Mastering Wire Cutting Techniques for Precision Engineering

-

5 Reasons Why Cables Connections Are Essential for Your Business Success

-

Innovative Examples of Best Wire Harness Manufacturing Practices in 2023

-

Comparing Harness Wires: Selecting the Optimal Option for Your Electrical Needs

Toll Free: (888) 802-2505

Phone: (256) 845-1255 or (256) 845-4493

Fax: (256) 845-1321 or (256) 845-4468

© 2025 Heritage Wire Harness, LLC