Blog

How to Effectively Harness Wire for Your Projects?

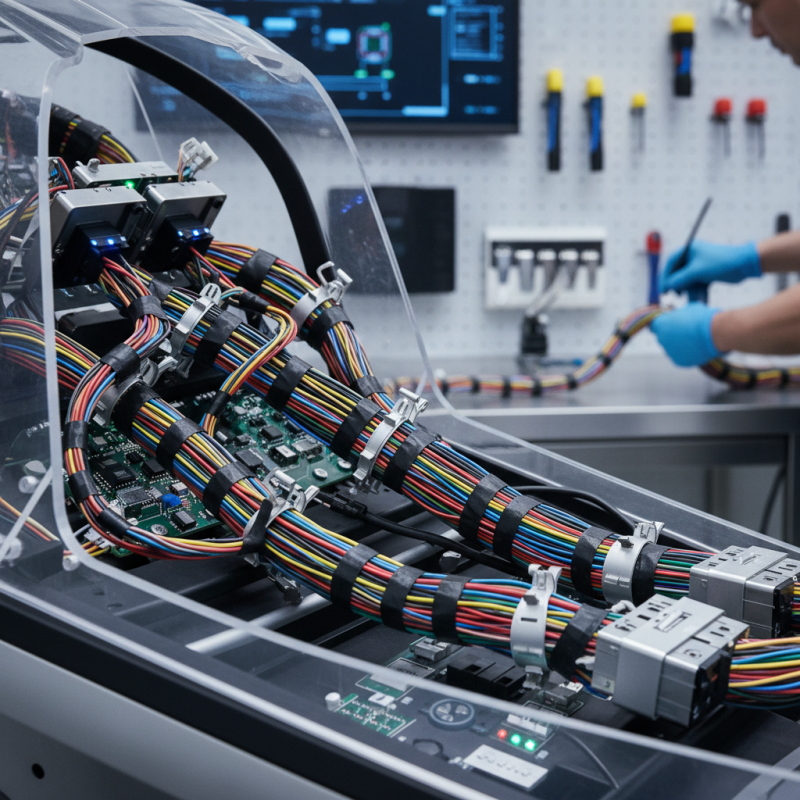

Harnessing wire has become essential in various industries. According to a recent report by the Global Wire Harness Market, the industry is expected to grow by 5% annually. This growth reflects the rising demand for structured electrical connectivity in automotive and aerospace sectors. Notably, the adoption of harness wire in consumer electronics has surged as well.

Understanding how to effectively harness wire can significantly improve project outcomes. For instance, using the right type of wire can enhance efficiency and safety. However, many overlook the importance of proper insulation and routing techniques. A study showed that poor wire management can lead to a 10% increase in maintenance costs. This statistic highlights the need for careful planning in projects.

Incorporating harness wire into designs isn't always straightforward. Errors in estimation and selection are common. Improper connections can lead to failures, affecting overall functionality. Thus, it is crucial to evaluate each project's unique requirements and avoid generalizations. Addressing these issues is key to achieving optimal results in any electrical project.

Understanding Different Types of Wire for Various Projects

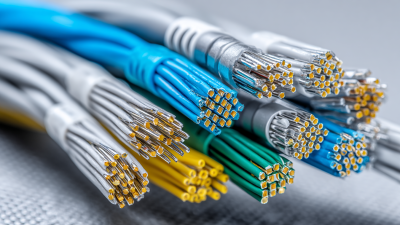

When it comes to projects, the type of wire you choose is vital. Different wires serve specific purposes, and understanding these distinctions can make a project more effective. For crafting, beading wire often works well. It is flexible and can easily hold beads in place. However, too much bending can cause it to break. This is a common mistake for beginners. Choosing the right gauge is also crucial. Thicker wires can be stronger but harder to twist.

For electrical tasks, insulated copper wire is the go-to option. It's durable and well-suited for carrying electric current. Improper stripping can lead to a failure in connections. Always measure the voltage needs carefully. Avoid assumptions about what wire will suffice.

In construction projects, galvanized wire is often chosen for fencing. It resists rust but requires skill to twist and shape properly. Many overlook the twisting technique, leading to weak structures.

Finally, a wire like aluminum is lightweight and easy to work with, yet it may not bear heavy loads like steel. Be aware of the limitations of each type. Making the right choice involves understanding their strengths and weaknesses. Explore different options and learn from the mistakes you make. Projects become more rewarding when you truly comprehend your materials.

Essential Tools and Materials for Working with Wire

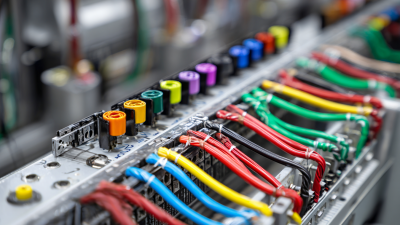

When working with wire, choosing the right tools and materials is crucial. A study by the National Craft Association reported that nearly 70% of DIY project failures stem from improper material use. Thus, having the right supplies can significantly impact the success of your wire projects. Essential tools include wire cutters, pliers, and a soldering iron. These tools allow for precise cutting, bending, and connection of wire, ensuring your project holds together.

Materials also play a vital role. Aluminum and copper wire are popular choices due to their flexibility and conductivity. For example, according to the Copper Development Association, copper wire is preferred for electrical purposes because it carries electricity efficiently. However, working with copper can sometimes be challenging due to its tendency to oxidize. This oxidation can affect connections, leading to failures.

Using lower-quality wire may save money initially, but it can lead to issues down the road. A report from the American Wire Association indicated that 40% of electrical problems are traced back to poor wiring materials. It’s essential to invest in high-quality wire for longevity. Remember to consider the gauge of wire as well. Thicker wire can handle more current, but it can also be more difficult to manipulate. Thus, finding a balance is key.

Techniques for Cutting and Shaping Wire Efficiently

When working with wire for your projects, efficient cutting and shaping are crucial. Proper techniques can elevate your work and save time. Using the right tools is essential. A quality wire cutter can make a clean cut and reduce frustrations. For shaping, pliers are your best friend. They help bend wire into precise forms without damaging it.

Tips: Always secure your wire in a sturdy position before cutting. This will ensure a straight, accurate cut. If you find yourself struggling, don’t hesitate to adjust your grip or the angle of your tools.

Experimenting with different techniques may lead to unexpected results. Sometimes, an imperfect bend can spark new ideas. Remember, wire responds unpredictably. Stay patient and keep trying. Adjusting the pressure can change the shape dramatically. Take your time to refine your approach.

Techniques for Cutting and Shaping Wire Efficiently

Safety Precautions When Handling Wire in Projects

Handling wire in projects can pose several safety risks. According to a report by the National Safety Council, over 20% of injuries related to hand tools involve cuts or lacerations. Wire can easily cause these injuries if not handled properly. Using gloves can prevent minor injuries, but they should be cut-resistant. Always inspect the wire for sharp edges before use. One small oversight can lead to significant accidents.

When working with wire, ensure your workspace is organized. A cluttered area can lead to trips and falls. According to industry data, over 30% of project-related injuries occur due to poor workspace organization. Keep your tools within reach and free of debris. This minimizes distractions and helps maintain focus. Don't attempt to handle wires while distracted. One moment of inattention can lead to serious injuries.

Proper storage of wire is also crucial. Unsecured coils can spring back and cause injury. Secure them with cords or clips. Use containers to organize smaller wire pieces. It’s easy to overlook these steps, yet they’re essential for a safe working environment. Pay attention to details. Safety is about the small things. Taking time to prepare and reflect on these safety measures can save you from unexpected injuries.

Creative Applications of Wire in DIY and Art Projects

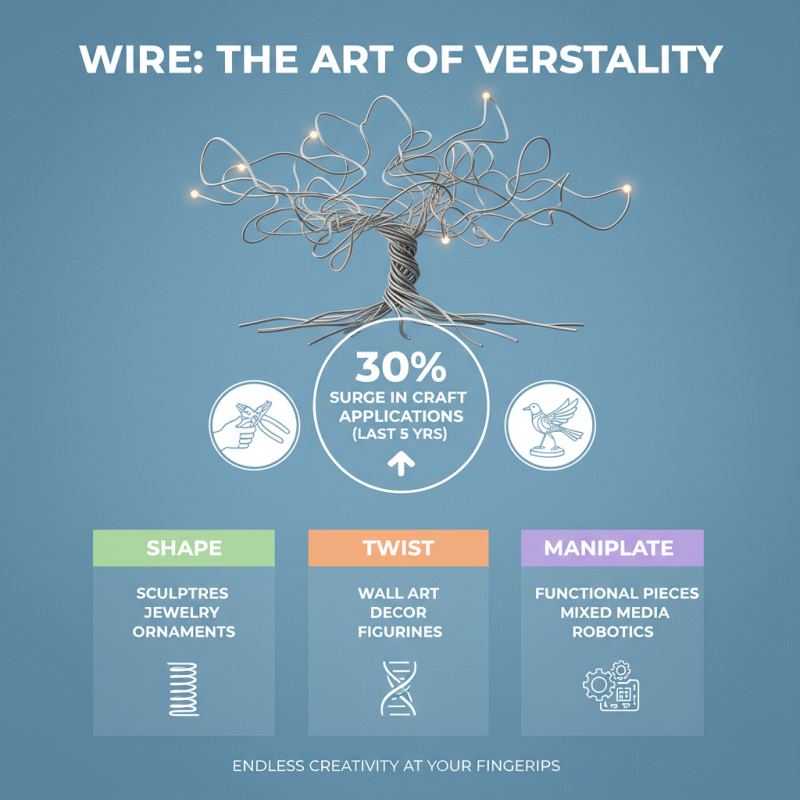

Wire is an incredibly versatile material for DIY and art projects. Many artists and creators harness its potential in unique ways. According to a recent industry report, wire applications in crafts have surged by 30% in the last five years. This growth reflects the rising interest in hands-on creativity. Wire can be shaped, twisted, and manipulated to create stunning artwork, sculptures, and functional pieces.

One creative application is wire sculpture. Artists often use aluminum or copper wire due to their flexibility. The process allows for improvisation, giving room for mistakes. These errors can lead to unexpected beauty. For instance, a bent wire may transform into an expressive curve in a figure. Embrace these imperfections; they add character to your project.

Tips: When working with wire, consider using pliers for clean cuts and bends. Always wear safety glasses to protect your eyes from sharp ends. Experimentation is key; test different wire types to see which fits your vision better. Consider creating wall art using wire to outline intricate designs. This technique adds dimension and depth, enriching your living space.

Explore other options too. Wire can be used in jewelry making, home decor, and even functional garden art. The possibilities are immense. Each twisted piece is an opportunity for unique expression. Keep experimenting and let your creativity flow freely.

Related Posts

-

Comparing Harness Wires: Selecting the Optimal Option for Your Electrical Needs

-

How to Choose the Best Wire Harness Manufacturing Solutions for Your Needs

-

Ultimate Guide to Mastering Wire Cutting Techniques for Precision Engineering

-

Understanding the Importance of Wire Harness Solutions in Modern Technology

-

7 Essential Features of the Best Wire Harness Equipment for Optimal Efficiency

-

Innovative Wire Harness Solutions Spotlighted at 2025 China 138th Canton Fair

Toll Free: (888) 802-2505

Phone: (256) 845-1255 or (256) 845-4493

Fax: (256) 845-1321 or (256) 845-4468

© 2025 Heritage Wire Harness, LLC