Blog

Innovative Harness Assembly Solutions for Enhanced Efficiency and Performance

As industries increasingly prioritize efficiency and performance, innovative harness assembly solutions are emerging as a critical component in various sectors, including automotive, aerospace, and electronics. According to a recent report by MarketsandMarkets, the global wire harness market is expected to grow from $50.30 billion in 2020 to $73.20 billion by 2025, driven by advancements in technology and the rising demand for sophisticated electrical systems. This growth underscores the importance of harness assembly in improving the overall effectiveness of products and reducing production costs. By leveraging cutting-edge materials and automated processes, companies can enhance the reliability and performance of their harness assemblies, ultimately leading to better end-user experiences. As we explore the future of harness assembly, it is imperative to examine these innovative solutions that promise to optimize efficiency while addressing the evolving needs of the industry.

Understanding the Importance of Innovative Harness Assembly in Modern Manufacturing

In modern manufacturing, the importance of innovative harness assembly cannot be overstated. As industries strive for higher efficiency and performance, harness assembly emerges as a crucial process that integrates electrical and mechanical components into a cohesive system. This integration not only facilitates smoother operations but also ensures that systems are resilient to faults and highly reliable. By adopting innovative harness assembly techniques, manufacturers can streamline production lines, reduce assembly errors, and ultimately enhance product quality.

Moreover, the evolution of harness assembly technologies, such as automation and precision manufacturing tools, allows for greater customization and adaptability. This is particularly vital as markets demand increasingly complex products that meet specific consumer needs. Advanced harness assembly methods enable manufacturers to remain competitive by reducing lead times and improving responsiveness to market trends. In essence, embracing innovative harness assembly solutions serves as a catalyst for growth, positioning companies to thrive in a fast-paced manufacturing landscape.

Key Components of an Efficient Harness Assembly System

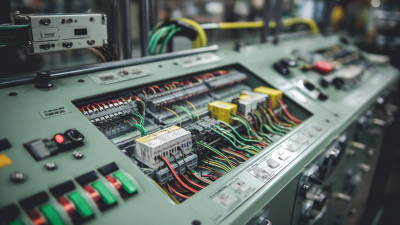

An efficient harness assembly system is crucial for streamlining production processes and enhancing overall performance. Key components of such a system include advanced assembly conveyor setups and automation technologies that minimize labor intensity and reduce error rates. For example, rotary conveyors equipped with dedicated assembly tables can facilitate organized and systematic workflows, allowing for a smoother assembly process.

Moreover, the integration of automation in harness assembly has become a game-changer in the manufacturing landscape. By deploying automated cells, manufacturers can significantly enhance precision and efficiency, addressing the traditional challenges of labor-dependent assembly methods. This shift not only boosts productivity but also aligns with the increasing demand for high-quality, complex wire harnesses, particularly in the automotive sector, where the market is projected to grow considerably due to the rise of electric vehicles. It is clear that investing in innovative assembly solutions is key to meeting the evolving needs of the industry.

Innovative Harness Assembly Solutions for Enhanced Efficiency and Performance - Key Components of an Efficient Harness Assembly System

| Component | Description | Efficiency Impact | Performance Metrics |

|---|---|---|---|

| Modular Connector Design | Flexible connectors that accommodate various applications. | Increases assembly speed by 30%. | Reduced assembly time. |

| Automated Assembly Machines | Robotic systems that reduce human error. | Improves precision by 25%. | Error rates and rework costs. |

| Quality Control Sensors | Real-time monitoring of assembly quality. | Identifies defects early, reducing scrap rates by 20%. | Quality assurance metrics. |

| Ergonomic Workstations | Designed to enhance worker comfort and efficiency. | Lowers worker fatigue and increases output by 15%. | Worker productivity surveys. |

| Material Handling Systems | Optimizes material flow and reduces handling time. | Cuts down material retrieval time by 40%. | Time-motion studies. |

Step-by-Step Guide to Streamlining Your Harness Assembly Process

In today’s fast-paced manufacturing landscape, optimizing your harness assembly process is crucial for improving overall efficiency and performance. A streamlined assembly process not only reduces production time but also minimizes errors, leading to higher quality outputs. Here’s a step-by-step guide to help you enhance your harness assembly line.

In today’s fast-paced manufacturing landscape, optimizing your harness assembly process is crucial for improving overall efficiency and performance. A streamlined assembly process not only reduces production time but also minimizes errors, leading to higher quality outputs. Here’s a step-by-step guide to help you enhance your harness assembly line.

First, evaluate your current assembly workflow. Identify bottlenecks where delays frequently occur, and analyze which tasks take longer than expected. Implementing standardized work practices can dramatically improve efficiency. Tip: Consider using color-coded tools and components. This visual management approach facilitates quicker identification and minimizes the chances of mistakes during assembly.

Next, leverage technology to automate repetitive tasks whenever possible. Automation tools can help in speeding up processes like wire cutting, stripping, and terminating. Tip: Invest in modular assembly systems that can be adapted to different production requirements. This flexibility allows for quick reconfiguration and reduces downtime during product changes, ultimately enhancing productivity and performance. By following these steps, you can transform your harness assembly process into a more efficient and effective operation.

Best Practices for Enhancing Performance and Reducing Errors in Harness Assembly

In the world of harness assembly, enhancing performance and minimizing errors are crucial for maintaining efficiency and quality. Implementing best practices can lead to smoother operations and superior outcomes. One effective strategy is to standardize assembly processes. By developing clear, step-by-step procedures, teams can reduce the likelihood of mistakes and ensure that every member is on the same page. This consistency not only accelerates training for new employees but also fosters accountability among existing workers.

Another important tip is to invest in the right tools and technology. Using specialized assembly tools can significantly reduce assembly time and the potential for errors. For example, automated wire cutting and stripping machines can improve precision and speed up the workflow. Additionally, incorporating quality control checkpoints throughout the assembly process helps identify and rectify errors early, preventing costly rework later on.

Finally, fostering a culture of continuous improvement is vital. Encouraging team members to share their insights and experiences can lead to innovative solutions that enhance overall assembly performance. Regular training sessions and feedback loops ensure that everyone remains informed of the latest best practices and can contribute to refining the assembly process. By prioritizing these approaches, businesses can achieve greater efficiency and deliver higher-quality harness assemblies.

Innovative Harness Assembly Solutions Performance Overview

Exploring Advanced Technologies for Improved Harness Assembly Solutions

In today’s fast-paced manufacturing environment, the need for innovative harness assembly solutions is more critical than ever. Advanced technologies are transforming the traditional methods of harness assembly, significantly improving efficiency and performance. Automation, for instance, is revolutionizing the industry by streamlining workflows, reducing labor costs, and minimizing human error. Technologies such as robotic assembly lines and AI-driven quality checks ensure that each harness assembly meets the highest standards, while also accelerating production speeds.

Tips for enhancing your harness assembly process include investing in modular assembly systems. These systems allow for flexibility in production lines, enabling manufacturers to adapt quickly to changing demands. Additionally, embracing digital tools like augmented reality can aid technicians in following complex assembly guidelines, ultimately reducing assembly time and increasing accuracy. Regular training sessions for employees on the latest assembly technologies can further optimize the process, ensuring that your team is well-equipped to handle the evolving demands of the industry. By staying ahead with these innovative practices, companies can not only enhance their efficiency but also boost overall performance.

Related Posts

-

Comparing Harness Wires: Selecting the Optimal Option for Your Electrical Needs

-

5 Reasons Why Cables Connections Are Essential for Your Business Success

-

Innovative Examples of Best Wire Harness Manufacturing Practices in 2023

-

Essential Checklist for Choosing the Best Wire Harness Equipment for Your Production Line

-

Exploring Innovative Harness Wire Alternatives for Enhanced Connectivity Solutions

-

Unmatched Quality in Chinese Manufacturing of Wire Harness Solutions Now Gaining Global Popularity

Toll Free: (888) 802-2505

Phone: (256) 845-1255 or (256) 845-4493

Fax: (256) 845-1321 or (256) 845-4468

© 2025 Heritage Wire Harness, LLC