Blog

Innovative Techniques for Streamlined Wire Harness Production

In the rapidly evolving landscape of manufacturing, wire harness production stands as a critical component in various industries, particularly in automotive and aerospace sectors. According to a report by MarketsandMarkets, the global wire harness market is projected to reach USD 66.4 billion by 2026, growing at a CAGR of 6.5% from 2021. This growth is driven by the increasing demand for advanced electrical systems and the integration of innovative technologies. To maintain competitiveness, manufacturers are now exploring innovative techniques to streamline wire harness production, minimizing waste and enhancing efficiency. This blog will provide a comprehensive checklist of cutting-edge strategies that can significantly improve production processes, ensuring that companies not only meet the rising demand but also achieve operational excellence in this crucial field.

Best Practices for Organizing Your Wire Harness Production Checklist

In the fast-paced world of wire harness production, maintaining organization is key to efficiency and quality. A well-structured production checklist can streamline operations and reduce errors. Start by categorizing tasks into distinct phases, such as design, material sourcing, assembly, and quality control. This helps team members understand their roles and the overall workflow at a glance.

Tip: Utilize digital tools to create your checklist, allowing for real-time updates and collaboration. This not only enhances communication but also ensures that all team members have access to the latest information, minimizing misunderstandings and delays.

Moreover, incorporate regular review points within your checklist to assess progress and address any bottlenecks promptly. Setting these milestones encourages accountability and keeps the momentum going throughout the production process.

Tip: Consider color-coding or prioritizing tasks based on urgency and importance. This visual cue can guide your team in focusing on what needs immediate attention, thus enhancing productivity and maintaining a smooth production flow.

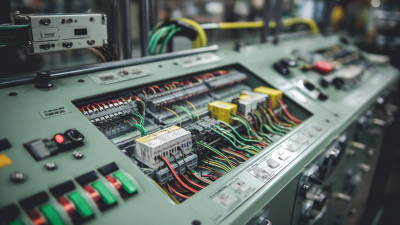

Essential Tools and Materials for Efficient Wire Harness Assembly

Wire harness assembly is a critical process in various industries, from automotive to aerospace, where efficiency is paramount. Essential tools and materials play a vital role in optimizing this production. According to a report by Market Research Future, the global automotive wiring harness market is expected to grow at a CAGR of 7.4% from 2021 to 2028. This growth highlights the increasing demand for specialized assembly tools such as automated crimping machines and advanced wire stripping tools, which significantly reduce manual labor and error rates.

Furthermore, the choice of materials is crucial for enhancing efficiency. High-quality insulation materials, such as cross-linked polyethylene (XLPE) and thermoplastic elastomers (TPE), not only provide superior durability and flexibility but also streamline the assembly process. A study by Research and Markets indicates that the use of innovative composite materials can reduce the weight of wire harnesses by up to 20%, leading to improved fuel efficiency in vehicles. Implementing these tools and materials can greatly enhance productivity while ensuring safety and reliability in wire harness production.

Innovative Techniques for Streamlined Wire Harness Production

Step-by-Step Guide to Developing a Comprehensive Production Checklist

In the ever-evolving automotive and electronics industries, creating a comprehensive production checklist is essential for achieving streamlined wire harness production. According to a report by MarketsandMarkets, the global wire harness market is expected to reach $75.2 billion by 2025, underscoring the critical need for efficient manufacturing processes. A well-structured checklist helps manufacturers minimize errors, enhance quality control, and boost overall productivity.

**Tip:** Begin by outlining the essential components of your production process. Include steps for material procurement, inspection protocols, assembly procedures, and quality assurance measures. Regularly reviewing and updating this checklist in response to industry trends and technological advancements can ensure your operations remain competitive.

Incorporating automated systems can also streamline workflow. A study from the International Journal of Advanced Manufacturing Technology shows that automation can reduce production time by up to 30%. This not only increases output but also allows for better allocation of human resources toward complex tasks that require specialized skills.

**Tip:** Invest in training your workforce to adapt to new technologies and encourage feedback on the production process. A knowledgeable team is integral to executing the checklist effectively and optimizing the production line for maximum efficiency.

Common Mistakes to Avoid in Wire Harness Production Planning

When it comes to wire harness production, careful planning is essential to avoid common pitfalls that can lead to increased costs and inefficiencies. One of the frequent mistakes in production planning is underestimating the complexity of the assembly process. A well-structured approach that incorporates detailed analysis and forecasting can significantly enhance the production workflow. By taking the time to understand the various components and their interactions, manufacturers can prevent bottlenecks and delays that are often caused by miscalculations or rushed timelines.

Another critical aspect is the implementation of a reliable enterprise resource planning (ERP) system. Such systems provide a holistic view of the production landscape, which is crucial for informed decision-making. An ERP can help track inventory, manage resources, and streamline communication across departments. By leveraging this technology, companies can minimize waste and optimize their supply chain operations. Moreover, integrating innovative techniques in wire harness production can further enhance efficiency, ensuring that businesses remain competitive while effectively reducing costs.

Effective Methods for Reviewing and Updating Your Production Checklist

In the fast-paced world of wire harness production, maintaining an effective production checklist is essential for optimizing efficiency and ensuring high-quality outcomes. One effective method for reviewing your checklist is to implement a regular audit schedule. By assessing the checklist at consistent intervals, teams can identify bottlenecks, redundancies, or outdated practices that might compromise productivity. This approach fosters a culture of continuous improvement and places emphasis on accountability within the production line.

Additionally, involving team members from various stages of the production process can provide invaluable insights during the checklist review. Encouraging feedback from operators, quality control inspectors, and engineers can reveal practical challenges that may not be immediately evident through management oversight alone. Collaborative brainstorming sessions can help to enhance the checklist, ensuring that it reflects the realities of the production environment while aligning with innovative techniques that facilitate streamlined operations. By integrating these methods, businesses can strengthen their production workflows and maintain a competitive edge in the industry.

Related Posts

-

Essential Checklist for Choosing the Best Wire Harness Equipment for Your Production Line

-

Unmatched Quality in Chinese Manufacturing of Wire Harness Solutions Now Gaining Global Popularity

-

Comparing Harness Wires: Selecting the Optimal Option for Your Electrical Needs

-

Exploring Innovative Harness Wire Alternatives for Enhanced Connectivity Solutions

-

Innovative Harness Assembly Solutions for Enhanced Efficiency and Performance

-

Innovative Examples of Best Wire Harness Manufacturing Practices in 2023

Toll Free: (888) 802-2505

Phone: (256) 845-1255 or (256) 845-4493

Fax: (256) 845-1321 or (256) 845-4468

© 2025 Heritage Wire Harness, LLC